Egyptian Government

Approves Methanol-to-Olefins

The Egyptian government has approved Eatco

Petrochemical’s (Cairo) $1.4-billion olefins and

polyolefins project at Damietta, Egypt. Eatco says it is looking

for partners for the project, which will use a new methanol-to-olefins (MTO) technology developed by UOP and Norsk

Hydro. Eatco will convert methanol to ethylene and propylene,

which will be supplied to plants with capacity for 300,000

m.t./year of polyethylene and 200,000 m.t./year of polypropylene.

Eatco says Dow Chemical, Chevron Phillips Chemical, and Basell

are competing to supply polyolefins technology. Eatco adds that

it is close to appointing a financial advisor.

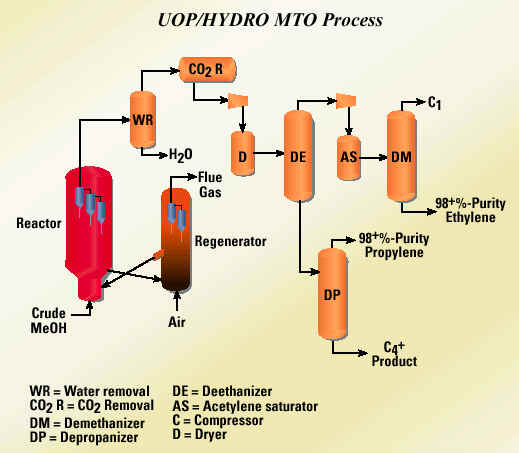

The MTOTM methanol to olefins process, developed by UOP and HYDRO of Norway, provides an economical means to convert methanol to olefins, primarily ethylene and propylene. Ethylene and propylene are in increasing demand worldwide and have significant financial value in the marketplace. With its higher yields, the MTO process is more economical than older technologies for indirect conversion of methane to higher value products.

The MTO process plays a key role in converting natural gas into olefins. The first step in that process, converting natural gas to methanol, has been available to the industry for some time. The second step, transforming the resulting methanol into olefins, is now available via the MTO process.

UOP/HYDRO MTO PROCESS

METHANOL TO OLEFINS CONVERSION

INTRODUCTION Changing natural gas into olefins is a two-step process

| The first

step, converting natural gas to crude methanol, has been

available to the industry for some time. The second step,

transforming the resulting methanol into olefins, has

recently been introduced by UOP and HYDRO of Norway. The

UOP/HYDRO MTO (methanol to olefins) process provides an

economical means to convert natural gas to olefins. The

UOP/HYDRO MTO process primarily converts the methanol

into ethylene and propylene. Ethylene and propylene are

in increasing demand worldwide and have significant

financial value in the marketplace. UOP and HYDRO have

developed the UOP/HYDRO MTO process for license to

customers worldwide. Other technologies for indirect conversion of methane to higher value products do exist. These processes have lower yields than the UOP/HYDRO MTO process and are, therefore, less economical. The UOP/HYDRO MTO process offers: |

|

| ・ | Exceptional value for direct conversion of methane to polymer-grade ethylene and propylene. |

| ・ | Direct use of ethylene and propylene in chemical-grade products with greater than 98% purity using a flowscheme that does not require expensive ethylene/ethane or propylene/propane splitters. |

| ・ | Limited production of by-products compared to a steam cracker, which results in a simplified product recovery section. |

| ・ | Easy integration into existing naphtha cracker facilities due to low paraffin yields. |

| ・ | Flexibility to change the ethylene to propylene product weight ratio from 1.5 to 0.75. |

APPLICATIONS

The UOP/HYDRO MTO process

can be utilized in locations with cheap, abundant natural gas

reserves. By integrating the UOP/HYDRO MTO process into a gas to

olefins (GTO) complex, feedstock prices can be held down and

natural gas can be converted into a form that is more easily

transported and of higher value. Existing naphtha or

ethane-propane cracker facilities can increase olefin production

and feedstock flexibility by installing an MTO reactor section

and feeding into a revamped cracker fractionation section to

minimize capital investment. Because the UOP/HYDRO MTO process

produces a rich olefinic effluent containing low quantities of

paraffins, the existing fractionation equipment can often be

easily debottlenecked to handle the additional olefins produced.

Yet another application would be downstream of an existing

methanol plant with excess capacity, to meet local demands for

olefins and polyolefins.

DESCRIPTION

In the UOP/HYDRO MTO

process, crude methanol is converted primarily to ethylene and

propylene. The process can work in either a maximum ethylene or a

maximum propylene production mode. The approximate purified

hydrocarbon product stream compositions, on the basis of wt%, are

shown below for both operating modes. By changing the reactor

operating severity, the UOP/HYDRO MTO process user can switch

between operation modes as market demands dictate.

Long-term methanol

conversion of 99.8% and stable product selectivity have been

demonstrated at HYDRO’s

large process demonstration plant in Norway. This plant

circulates and regenerates catalyst continuously and uses crude

methanol as a feedstock at a rate of more than 0.75 MT per day.

The UOP/HYDRO MTO

commercial process utilizes a fluidized bed reactor with a

continuous fluidized bed regenerator. This technology is an

extension of UOP’s

established FCC commercial technology.

Component(wt%) Maximum

Ethylene ModeMaximum

Propylene ModeEthylene

48%

34%

Propylene

31%

45%

Butenes

9%

12%

C 2 =/C 3 =

1.5

0.75

FEEDSTOCKS

Feedstock for the

UOP/HYDRO MTO process is crude, non-distilled methanol usually

produced from synthesis gas (CO + H 2 ), which is produced from

the reforming of abundant natural gas. Synthesis gas can also be

produced by steam reforming of petroleum products such as

naphtha, partial oxidation of natural gas and petroleum products,

and coal gasification.

CATALYST

The reaction is catalyzed

by the MTO-100 silicoaluminophosphate synthetic molecular sieve

based catalyst. The catalyst has demonstrated the degree of

attrition resistance and stability required to handle multiple

regenerations and fluidized bed conditions over the long term.

The catalyst is extremely selective toward the production of

ethylene and propylene.