JSC Sibur Holding 詳細

http://www.sibur.ru/eng/articles/Main_01.shtml

JSC SIBUR Holding is a vertically integrated setup that processes considerable volumes of hydrocarbon stock in Russia all along the line starting from primary treatment all the way to consumer product manufacturing. The enterprises that make up the Holding produce over one hundred petrochemical products

Gazprombank planning to sell its stake in petrochemicals business Sibur

Gazprom completes move to fully divest petchems business Sibur

RIL and Sibur to jointly pioneer Butyl Rubber production in India

SIBUR and Sinopec plan two joint ventures for NBR and extend their cooperation

Sibur-Sinopec Rubber Holding Company Limited is a joint venture between SIBUR and China Petroleum and Chemical Corporation (Sinopec Corp.) developed on the site of the Krasnoyarsk Synthetic Rubber Plant (KZSK) to produce nitrile butadiene rubbers. SIBUR owns 74.99% of the JV.

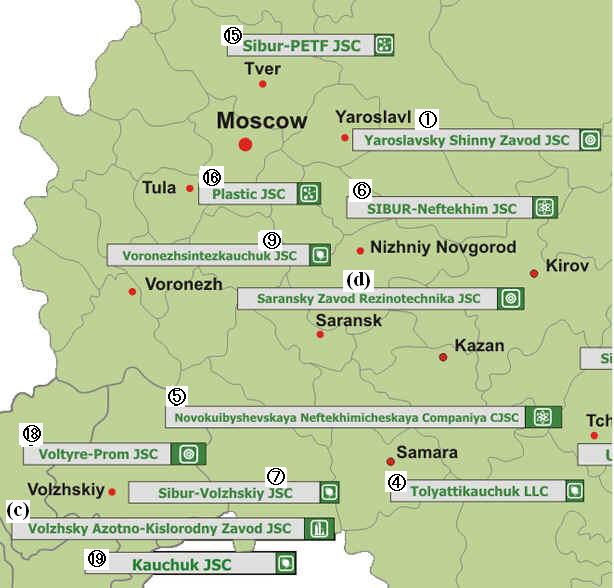

全体地図

| 西部地図 |

|

| 東部地図 |

|

Gazprombank mulls sale of

stake in petchem unit Sibur

Russia's Gazprombank was planning to sell its stake in

petrochemicals business Sibur, business daily Vedomosti

reported Tuesday, citing a Eurobond prospectus.

http://www.knak.jp/others/russia-jsc-sibur.htm

The report said Gazprombank could sell its stake of 75% minus one

share in Sibur to an investor. Gazprombank may also consider

listing the shares, Vedomosti said. The remaining stake in Sibur

of 25% plus one share is owned by Gazprom, Vedomosti said.

Gazprombank would not comment on the report.

According to Vedomosti, Gazprombank itself is currently 42%-owned

by Gazprom, after Gazprom cut its share in the bank last year.

This figure could not be immediately confirmed by either company.

Gazprom completes move to fully

divest petchems business Sibur

-

平成20年4月15日 東洋エンジニアリング

ロシア向けエチルベンゼン(EB)生産設備を受注

東洋エンジニアリング株式会社(TEC、取締役社長

山田 豊)は、伊藤忠商事株式会社(取締役社長

小林栄三)と協力し、当社の韓国現地法人であるトーヨーコリア社(Toyo-Korea、取締役社長 菅屋直樹)とともに、ロシア連邦シブール Sibur-Khimprom CJSC (Perm)社がペルミ

Perm市に建設を計画する22万トンのエチルベンゼン(EB)生産設備をこのたび受注いたしました。本プロジェクトには米バジャー社の技術が採用されており、Toyo-KoreaとTECは基本設計、詳細設計、機器調達及び工事テクニカルアドバイザリーサービスを実施し、プラントの完成は2010年末を予定しています。

シブール社が同時に計画しているエチレン増産、スチレンモノマー増産、発泡ポリスチレン新設とともにポリマーコンプレックスの一翼を担う。

The ethylbenzene plant is a part of SIBUR's investment plans, which include the construction of a 150,000 mt/year expandable polystyrene facility, and the expansion of its ethylene production facility.

SIBUR has a long-term investment program consisting of a series of projects, aimed at increasing its local market share as well as expanding its exports.

SIBUR plans to expand its ethylene production capacity in the Nizhny Novgorod region to 360,000 mt/year by the end of 2010. Its steam cracker there currently has the capacity to produce 240,000 mt/year of ethylene.---

April 11, 2008 SIBUR

SIBUR Selects Engineering Company for Construction of Ethyl Benzene Plant in Perm

Sibur-Khimprom CJSC (Perm) has signed a contract with Korean company TOYO for engineering, procurement and installation support for a planned new ethyl benzene plant with a capacity of 220,000 tonnes per annum (tpa). The facility is expected to come on stream in late 2010.

In 2007, US company Badger Licensing LLC was selected as licensor and designer of the new plant. It will use the most up-to-date technology based on zeolite catalysts, thereby completely eliminating atmospheric emissions of hydrogen chloride and aromatic hydrocarbons, as well as contamination of effluent by chlorides, aluminium salts and phenols.

The new ethyl benzene facility will supply feedstock for the planned increase in styrene and polystyrene production at the company's plants. Sibur-Khimprom, in particular, plans to renovate its styrene facility, boosting production capacity from 100,000 to 135,000 tpa, and to build a new 50,000 tpa polystyrene plant that will be expanded in future to 100,000 tpa.

Technology developed by the Norwegian company Sunpor Technology S.A. will be used at the EPS production facility.

SIBUR’s Tobolsk Polypropylene Plant Enters Construction Phase

Today the President of

SIBUR, Dmitriy Konov, and the Deputy Governor of Tyumen Region,

Aleksandr Moor, took part in the openning ceremony of the

construction site of the future polypropylene plant in Tobolsk.

Launch of the new plant is scheduled for 2011. It will be the

largest such facility in the world with a design capacity

of 500,000 t of polypropylene per year.

Project Timeline

| April 2006 | SIBUR creates fully-owned subsidiary LLC “Tobolsk-Polimer” to handle the project. |

| January 2007 | SIBUR selects US company Fluor (Project Management Company) as project manager. |

| February 2007 | SIBUR signs agreement with Government of Tyumen Region on joint construction of housing partly intended for builders and staff of the new plant. |

| August 2007 | SIBUR and project manager FLUOR jointly select proprietary technologies: UOP (US) and INEOS (US). |

| August 2007 | Government of Tyumen Region and LLC “Tobolsk-Polimer” sign investment agreement on state support for the project. |

| December 2007 | SIBUR selects Italian company Tecnimont S.p.A and German company Linde-KCA-Dresden as contractors for front-end design, equipment supply and construction management. |

| June 2008 | The people of Tobolsk give their support to the project at a public hearing. |

2007/7/6 Solvay、ロシアでワールドクラスの塩ビJV Sibur 2008/4/21 東洋エンジニアリング、ロシア向けエチルベンゼン生産設備を受注 Sibur

Sibur picks UOP and INEOS processes for Tobolsk

UOP propane dehydrogenation technology and INEOS (Innovene) polypropylene (PP) technology will be used at the Tobolsk-Polymer complex in Russia’s Tyumen region, Sibur said on Monday.

The company says its planned 510,000 tone/year PDH unit with gas producer Novatek will be the world’s largest. The project includes a world-scale 500,000 tonne/year PP unit.

The 100% Sibur-owned subsidiary Tobolsk-Polymer was created in April 2006 to develop the project and engineering contractors Fluor were chosen in January 2007 to manage the project which was given the go-ahead from Tyumen regional authorities in February.

Sibur currently can produce 110,000 tonne a year of PP.

The first-phased Tobolsk project is planned to be on-stream y the end of 2010, Sibur chief executive, Dmitry Konov, said at the beginning of July. Sibur’s second phase plans for Tobolsk include elfins, PP and polyethylene capacity additions.

At the beginning of 2006 the Board of Directors of SIBUR Holding JSC decided to establish a 100 per cent subsidiary, Tobolsk-Polymer LLC in the city of Tobolsk. This company focuses on the supervision and construction of production facilities for liquefied gas processing at the production site of Tobolsk-Neftekhim LLC.

A Declaration of Intensions to construct a propylene and polypropylene production site with a capacity of 500 KTA of polypropylene was forwarded and approved by the local authorities.

Tobolsk-Neftekhim JSC

A modern plant designed for processing of NGLs and comprising:

- LPG production - propane, isobutene, n-butane, isopentane, n-pentane, hexane;

- Production of monomers for the synthetic rubbers industry - butadiene, isobutylene;

- Production of MTBE - a high-octane additive for motor gasolines.

INEOS Technologies signs further agreement with Sibur LLC

Sibur LLC has selected INEOS' Innovene PP Process for a new 200,000 tpa polypropylene plant to be constructed at the production site of Tomskneftekhim LLC, Tomsk, Russian Federation.

This will be Sibur's second polypropylene plant using INEOS process technology. Previously, Sibur used INEOS’ Innovene polypropylene process technology for a proposed 500,000 tonne/year PP plant at Tobolsk, Russia.

Under the deal, Sibur plans to sell and Tatneft plans to acquire certain production and other assets that are currently registered in the name of Sibur Togliatti and Togliattisintez legal entities.

The assets include production facilities for various types of synthetic rubber used by Russia’s and the world’s leading tire manufacturers, for MTBE (high-octane fuel component), butadiene, isoprene and other intermediates, as well as infrastructure of the industrial park accommodating a number of chemical and other technological companies.

For Tatneft, the acquisition is an opportunity to strengthen the vertical integration of its Kama Tyres business and increase its value.

After the acquisition, Tatneft intends to further develop the assets in line with its gas and petrochemical strategy.

Sibur, with its focus on establishing and developing global scale production of basic polymers, high-potential medium-tonnage products and premium special chemicals, will continue to cooperate with the Togliatti-based companies as partners.

The deal is expected to be closed by the end of 2019, including all corporate procedures, antitrust approvals and other statutory formalities.