IPCL Indian Petrochemicals Ltd

歴史 IPCL Homepageより http://www.ipcl.co.in/ipcl/about/history.htm#hd

Board of Directors of IPCL and RIL approve merger

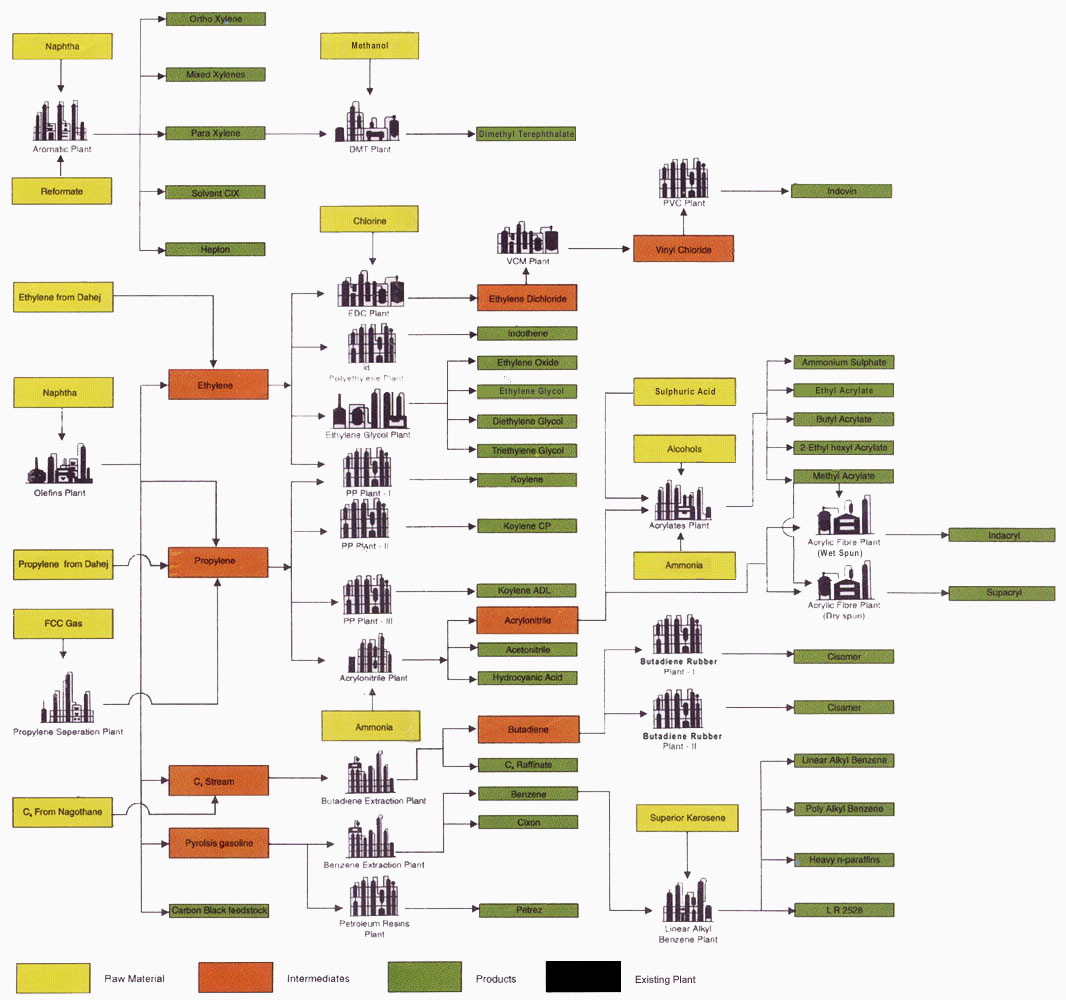

IPCL one of the leading integrated petrochemical players in India is (was)owned 60% by the government of India. The company manufactures petrochemical products (polymers, fibre and fibre intermediates and chemicals) using hydrocarbon feed stocks naphtha and natural gas.

It has Vadodara complex、Nagothane complex、and Gandhar complex.

2002/5 Reliance buys Indian Petrochemicals Corp

The Government of India handed over the Management control to Reliance group on June 4, 2002, since then the company is being managed by Reliance. The new management team has re-endorsed the company's mission to create value for all stakeholders. All out efforts are being made to enhance productivity and control cost for superior value addition.

Platts 2003/7/10

Indian govt to sell remaining 26% stake in Indian

Petrochemical

India's Cabinet Committee on Disinvestment, a panel headed by

Prime Minister Atal Behari Vajpayee, Thursday decided to sell its

remaining 26% stake in Indian Petrochemical Corp.

事業 http://www.ipcl.co.in/ipcl/about/nagothane.htm#hd

Vadodara complex:

The foundation stone for the Gujarat Olefins Project ( Naphtha Cracker) was laid by Mrs. Indira Gandhi, the then Prime Minister of India on January 29, 1972.

A fully integrated petrochemical complex under a single ownership, being the first of its kind in the Indian peninsula, came into existence. The complex was dedicated to the nation by Mr. Morarji R. Desai, the then Prime Minister of India on March, 30, 1979.

Nagothane complex:

The foundation stone of this complex was laid by Mr. N. D. Tiwari, the then Minister of Industry, Government of India on January 8, 1986. Detailed engineering and project management for Nagothane Complex was entrusted to EIL, which involved setting up of a Gas Cracker plant of 300,000 TPA of ethylene, 80,000 TPA of ldPE, 50,000 TPA of MEG, 5000 TPA of EO, two units of 80,000 TPA each of hdPE/lldPE, one unit of 15,000 TPA of Butene-1, one unit of 12,000 TPA of Wire & Cable and supporting off-site utilities and storage.

The cracker, along with the low density polyethylene, monoethylene glycol and polypropylene plants, were stabilized in the first quarter of 1992. Subsequently, the butene-1 plant and one stream of lldPE/hdPE swing plant were commissioned.

The concept of economy of scale with built in flexibility for future expansion during mid eighties required a cracker having capacity of 300,000 MTA ethylene. Flexibility was incorporated in the design itself to expand the capacity to 400,000 MTA ethylene by addition of one heater. This design flexibility has been fully exploited as additional feed stock is now available for cracking. The cracker capacity now stands expanded to 400,000 MTA of ethylene, since the second quarter of 1998.The company is examining the possibility of expanding the ethylene capacity to 550,000 MTA with expansion of lldPE/hdPE and an alpha Olefins plant of 50,000 MTA.

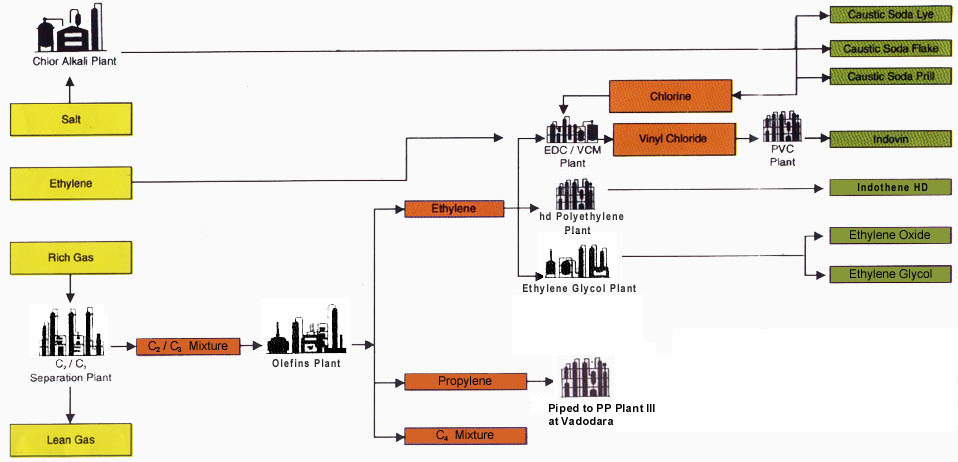

Gandhar complex(Dahej complex)in the Gandhar region:

The Dahej complex is a consequence of the discovery of large scale reserves of oil and gas in the Gandhar region. The availability of raw materials like salt and access to a sea, besides hydrocarbon feed stock and good water sources in river Narmada offer a favourable environment for petrochemicals industries in the region.

Phase I

The first phase consisted of 170,000 tonnes/year vinyl chloride monomer (VCM) plant, 150,000 tonnes/year polyvinyl chloride (PVC) plant (later expanded to 180,000 tonnes/year), chlor-alkali plant with 115,000 tonnes/year of chlorine and 130,000 tonnes/year caustic soda (which will produce 40,000 tonnes of 50% lye, 45,000 tonnes flakes and 45,000 tonnes of prills) and 65MW power plant. These plants were all commissioned in fourth quarter of 1996.

Phase II

In the phase II, a gas cracker of 300,000 tonnes/year of ethylene, 160,000 tonnes/year HDPE and 100,000 tonnes/year of ethylene oxide/glycol plants were built. The second phase plants have been commissioned during the accounting year 1999-2000. The last set of plants of the second phase; gas cracker and C2/C3 separation unit were commissioned in February 2000 (Vasant Panchmi). Flexibility to expand the cracker to 400,000 tonnes/year of ethylene has also been built in during the design stage. After the addition of balancing equipment, this can also be raised to 500,000 tonnes/year of ethylene.

http://www.plastics-technology.com/projects/dahej/

JV

GE Plastics India: IPCL has contributed over Rs250mn in a 50:50 joint venture with General Electric Plastics BV. GEP manufacturers engineering plastics with latest technology.

IPCL has decided to pullout from this business.The negotiations for sale of IPCL's stakes to GE Plastics, BV, Nethelands is in advance stage and are expected to be completed very soon.