President Khatami launches Sanandaj LDPE plant

http://www.nipc.net/npcnews/news54/projects.htm

他のページへ トップページ アジアの石油化学 連絡先 knak@js2.so-net.ne.jp |

Petrochemical Special Economic

Zone

http://www.nipc.net/npcg/2001/Special.html

Projects being executed in the Petzone are as follows: * Intermediate product

| Projects | Products | Capacity 1000T/Y |

| MTBE Owner: Petrochemical Industries Development Management Co. (PIDMCO) Ownership: NPC (100%) Site: BIPC Project starting date: 1997 Status: Completed |

MTBE | 500 |

| 1st PTA/PET

Owner: Shahid Toondguyan Petrochemical Co. Ownership: NPC (100%) Project starting date: 1997 Completion date: 2003 |

*PTA Fiber-Grade PET Bottle-Grade PET |

350 |

| 6th Olefin Owner: Amir Kabir Petrochemical Co. Ownership: NPC (84%), Social Security Organization (12%), Others (4%) Project starting date: 1998 Completion date: 2002-2003 |

*Ethylene *Butene-1 *C4 Cut Propylene HDPE LLDPE Ethylene Fuel oil Butadiene Ext. Pyrolysis Gasoline |

520 |

| 3rd

Aromatics Owner: Bou Ali Sina Petrochemical Co. Ownership: NPC (100%) Project stating date: 1998 Completion date: 2003 |

Orthoxylene

Paraxylene Benzene Liquified Gas Raffinate Light Ends Heavy Ends Heavy Aromatics C5 ’Cut |

30 |

| Centaralized

utility plant Owner: Fajr Petrochemical Co. Ownership: NPC (100%) Project starting date: 1998 Completion date: 2002 |

Electricity

Steam Instrument air Service air Oxygen Nitrogen Service water Potable water D.M. water Boiler Feed water |

585 MW |

| Engineering

Polymers Owner: Khuzestan Petrochemical Co. Ownership: NPC (100%) Project starting date: 1998 Completion date: 2003 |

Polycarbonate

Solid epoxy resins Liquid epoxy resins |

25 |

| 2nd PTA/PET

Owner: Shahid Toondguyan Petrochemical Co. Ownership: NPC (100%) Project starting date: 1999 Completion date: 2004 |

*PTA PTA Fiber-grade PET Bottle-grade PET Polyester Staple Fiber Polyester Filament |

350 |

| 3rd

Methanol Owner: Fanavaran Petrochemical Co. Ownership: NPC (100%) Project starting date: 2000-2001 Completion date: 2003-2004 |

*Methanol *CO Methanol Acetic Acid CO |

1000 |

| LDPE (7th

Olefin) Owner: Laleh Petrochemical Co. Ownership: Sabic Europe Petrochemical Ltd. (30%), Marun (45%), Pushineh Iran (25%) |

LDPE | 300 |

| 7th Olefin Owner: Marun Petrochemical Co. Ownership: NPC (100%) Project starting date: 2000 Completion date: 2004 |

*Ethylene *Propylene *Pyrolysis Gasoline *C2+ LDPE PP Ethylene HDPE MEG DEG |

1,100 |

| Isocyanates

Owner: Karun Petrochemical Co. Ownership: NPC (40%), Chematur A.B. (30%), Hansa Chimie (30%) Project stating date: 2001 Completion date: 2004-2005 |

Toluene

diisocyanate (TDI) Diphenylmethane diisocyanate (MDI) *Carbonyl Di-chloride *Anilyne *Nitric Acid |

40 |

A polypropylene plant contract is awarded to Tecnimont-Nargan

http://www.nipc.net/npcnews/news8and9/projects.htmlThe National Petrochemical Company (NPC) awarded, on September 17, 2000, the contract for a polypropylene (PP) plant of its 7th olefin facility to Italy's Tecnimont SPA. The plant will be built in Bandar Imam, Petrochemical Special Economic Zone (Petzone). The 300 Kt/a homopolymer/copolymer polypropylene plant will be based on the Montel's technology.

The contract calls for the provision of license, basic engineering, supply of equipment and technical assistance.

The plant will be fed by Marun (olefin no. 7) Complex's 1.1m t/y ethylene cracker. Marun Petrochemical Company, which is an NPC subsidiary will implement and

run the project.

Tecnimont's partner, Iran's Nargan will provide the detailed engineering and those pieces of equipment that are manufactured locally. The facility will be supplied within 24 months.

2003/5/21 Asia Chemical

Weekly

Iran's NPC to start up engineering polymers project Q3 '03

Iran's National Petrochemical Co (NPC) expects to start up its $198m (Euro170.1m) engineering polymers facility in the Petrochemical Special Economic Zone in the third quarter of 2003 having already completed 93% of the project, according to the NPC's latest news bulletin.

イランNPC、メタ100万トン設備が来月末稼働

イランNPC(国営石油化学会社)が建設を進めている年産100万トンのメタノール設備が、9月末に稼働する見通しとなった。

Shell, Basell suspend Iran's

Olefins No8 for now

http://www.chemweekly.com/ReadNews.asp?NewsID=919&BigClassName=Companies&BigClassID=25&SmallClassID=43&SpecialID=24

Shell Chemicals and Basell have withdrawn from the Olefins No 8 project in Iran for the time being because of a disagreement over timing, according to Rein Willems, Shell's executive vice president, business and procurement units.

However, Willems has stressed that the exit is not a done deal and that the door to re-enter the project remains open for Shell and Basell, who had originally considered taking a combined 50% stake.

ITBs issued for Olefin No.11

cracker

http://www.nipc.net/npcnews/news45-46/projects.htm

NPC has issued invitation-to-bid

(ITB) documents to interested contractors for its worldscale

Olefin No. 11 project, which will be built at the Pars Special

Economic/Energy Zone in Assaluyeh. The complex will consist of an

ethylene

cracker with a capacity of 1,200,000 tonne/year.

Downstream units of the complex include a 300,000 tonne/year of

high-density polyethylene (hdPE) plant, a 300,000 tonne/year of

linear low-density polyethylene (lldPE)/high-density polyethylene

(hdPE) unit, a 50,000 tonne/year 1-butene facility, a 700,000

tonne/year monoethylene glycol (MEG) plant and a 600,000

tonne/year styrene monomer (SM) unit.

The last date for submission of bids is 1 April 2004.

NPC News Bulletin Nov-Dec,2003

http://www.nipc.net/npcnews/news45-46/projects.htm

Iran's share of global methanol

output to reach 6.4%

NPC is set to expand its methanol capacity from 740,000

tonne/year in 2003 to 3.4m tonne/year by 2005. The availability

of natural gas in Assaluyeh and Bandar Imam is at the heart of

NPC's plans to build two mega-methanol projects with a combined

capacity of 2.65m tonne/year increasing its share of the global

methanol market from 1.5% to 6.4%. NPC's third methanol facility, is under construction at Petrochemical

Special Economic Zone near Mahshahr. The plant, which is being

implemented by Fanavaran Petrochemical Co. has a capacity of 1m

tonne/year. It is already 98% complete and is expected to come

onstream in early 2004. The complex will consume 610,000

tonne/year of natural gas and 330,000 tonne/year of CO2 which

will be supplied locally.

Fanavaran is also building a 150,000 tonne/year acetic acid

project and a 140,000 tonne/year carbon monoxide (CO) unit

downstream of the methanol plant. Both of these plants are slated

to come onstream by the end of 2004. About three-quarters of the

methanol plant's capacity will be exported while 82,000

tonne/year of its output will feed its acetic acid plant. It will

also supply Bandar Imam Petrochemical Complex with 178,000

tonne/year of methanol.

In addition to its No. 3 methanol plant, NPC is building a 1.65m tonne/year methanol plant in the Pars Special Economic/Energy Zone

in Assaluyeh. The fourth methanol project is being implemented by

Zagross Petrochemical Co. It is already 67% complete and is

expected to be commissioned in Q1 of 2005. The complex feedstock

includes 188,000sm3/hr of natural gas and 83,000sm3/hr of oxygen.

NPC already has two methanol facilities operating in Kharg Island and Shiraz with a combined capacity of 744,000

tonne/year.

NPC Aug. 2004 (No.54)

President Khatami launches Sanandaj LDPE plant

http://www.nipc.net/npcnews/news54/projects.htm

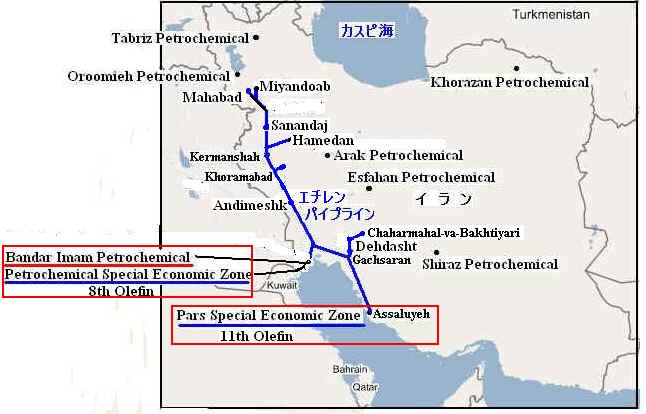

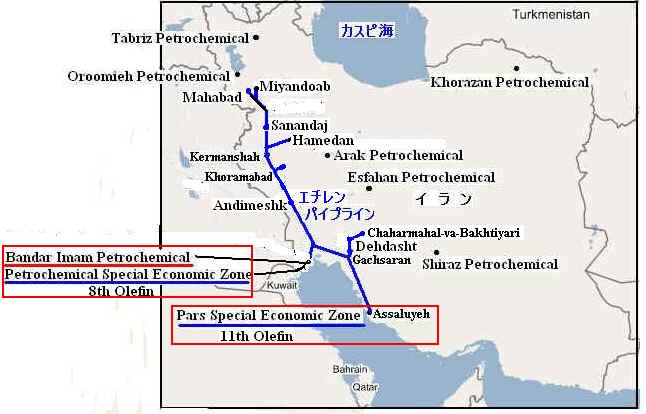

Iranian President Seyyed Mohammad Khatami broke the ground for a 300,000 tonne/year low-density polyethylene project in Sanandaj, the provincial capital of Iran's western Kurdestan province. The plant will take 4 years to complete. It will use 303,000 tonnes of ethylene and 5,000 tonnes of propylene as raw materials per year. The required ethylene feedstock will be supplied through a 1500km pipeline which extends from the Pars Special Economic/Energy Zone in Assaluyeh. The project, to be built in an area of 143 hectares, will create 200 job opportunities playing a direct role in developing downstream industries in the region.

The ethylene pipeline will run from Assaluyeh to Gachsaran, Khoramabad, Kermanshah, Sanandaj and Mahabad along the western provinces of Iran. Mahabad is now the terminus of the project. A local producer will supply the pipes. In addition to the ldPE plant in Sanandaj, at least seven other petrochemical facilities, will be built along the course of the pipeline. These plants include an ethylene glycol (EG) and an ethylene oxide (EO) plant in Kohgiloyeh-va-Boyerahmad province, a swing linear low-density polyethyelen (lldPE)/high-density polyethylene (hdPE) complex and a butane-1 plant in Lorestan province, a high-density polyethylene (hdPE) facility in Kermanshah province and a linear low-density polyethylene (lldPE)/high-density polyethylene (hdPE) facility plus a butane-1 plant in Western Azarbaijan province. Speaking at the ground breaking ceremony, President Khatami said the construction of the Assaluyeh-Mahabad ethylene pipeline and the planned petrochemical facilities to be built along its course, would have far-reaching benefits stimulating growth in the western provinces. The Government of the Islamic Republic of Iran will fully finance the ethylene pipeline project. President Khatami added that the petrochemical plants would be developed with the participation of the private sector.

August 5, 2005 British Plastics & Rubber

Basell to license more PE production in Iran

Iran's National Petrochemical Company - recently squeezed out from buying Basell - is buying another licence to use a Basell process. Its affiliate Kurdestan Petrochemical Company is to use Basell's Lupotech T technology for a new LDPE plant in Sanandaj in Kurdestan province, Iran. The plant will have an annual capacity of 300,000 tonnes and start-up is planned for 2008.

The new plant will be part of NPC's 11th Olefin project. Ethylene feedstock will be supplied from an ethane gas cracker located at Al Assaluyeh. A 1,500 kilometre pipeline will connect the cracker with five petrochemical sites located in the western provinces of Iran. In addition to the new Lupotech T plant, the 11th Olefin project includes a 300,000 tonnes HDPE plant (Kermanshah) using Basell's Hostalen process and two 300,000 tonnes LLDPE/HDPE plants(Lorestan & Western Azarbaijan).

This latest Lupotech T license is the 13th license granted by Basell for projects in Iran with a combined annual capacity of more than 3.1 million tonnes. Other technologies licensed by Basell in Iran include Spherilene, Lupotech G and Hostalen polyethylene technologies and Spheripol polypropylene.

NPC News Bulletin Oct-Nov.2005

Kordestan Petrochemical Company

Kordestan plant will produce 300,000 tonne/year of low density polyethylene (ldPE) in various grades for domestic consumption and export. The plant will be based on Basell Polyolefin Lupotech Technology. It will be located at Sanandaj, Kordestan province, northwest of Iran. A consortium of Tecnimont of Italy & PIDEC of Iran have been awarded the engineering, procurement, construction and commissioning (EPCC) contract to construct the facility. The contract covers grant of license, basic and detailed engineering, supply of equipment and materials, construction, erection, pre-commissioning, commissioning, start-up and performance tests. The plant will consume 303,000 tonne/year of ethylene as feed, which will be supplied by the 11th olefin plant through the West Ethylene Pipeline. It will also need 1,000 tonne/year of propylene which will be sourced locally. Utilities, including power, water and steam will be supplied by the utilities plant of Kordestan petrochemical complex. Kordestan Petrochemical Company, which is 100% owned by Bakhtar, is implementing and will operate the facility.

NPC News Bulletin July 2005 No.65

Kordestan Petrochemical Co. selects contractors for its LDPE project

Kordestan Petrochemical Company of Iran has awarded an "EPCC" contract to a consortium of Tecnimont of Italy & PIDEC of Iran to construct a Low Density Polyethylene plant in Sanandaj, Kordestan province, northwest of Iran. The plant which will be based on Basell Polyolefin LUPOTECH Technology, will produce 300,000 tonne/year of LDPE in various grades for domestic consumption and export. The plant will consume 303,000 tonne/year of ethylene as feed, which will be supplied by the 11th olefin plant complex through West ethylene Pipeline. Utilities, including power, water and steam will be supplied by the utilities plant of Kordestan petrochemical complex. The contract covers grant of license, basic and detailed engineering, supply of equipment and materials, construction, erection, pre-commissioning, commissioning start-up and performance tests. The plant is scheduled to be completed in 38 months. Kordestan Petrochemical Company is implementing and will operate the facility.

NPC News

Bulletin Sept 2004 No.55

President Khatami: "Petchem industry a buttress to Iran's

economy and industry"

ーPresident broke

the ground for the Mahabad Petrochemical Complexー

Iranian

President Seyyed Mohammad Khatami broke the ground for the Mahabad Petrochemical Complex. The facility

will consist of a swing 300,000 tonne/year linear

low-density polyethylene/high-density polyethylene (lldPE/hdPE)

plant and a 30,000 tonne/year 1-butene unit. It will be built

in the city of Mahabad, Iran's Western Azerbaijan

province. The facility will consume 324,000

tonne/year of ethylene which will be supplied through a 1500km

pipeline which extends from the Pars Special Economic/Energy Zone

in Assaluyeh.

The ethylene

pipeline will run from Assaluyeh to

Gachsaran, Khoramabad, Kermanshah, Sanandaj and Mahabad along the

western provinces of Iran. The construction of the

Assaluyeh-Mahabad ethylene pipeline and the planned petrochemical

facilities on its route is believed to have extensive benefits

including the growth of downstream industries. The Government of

the Islamic Republic of Iran will finance the ethylene pipeline

project while the petrochemical plants will be developed with the

participation of the private sector.

Speaking at the ground breaking ceremony, President Khatami said

" the efforts that have been done and are being done for the

growth of the petrochemical industry are a great buttress to the

nation's economy and industry" adding that NPC's export will

reach $1.8bn at the end of the current Iranian year in March

2005. He said the decision to build the complex was a decision in

the right direction.

NPC News Bulletin Oct-Nov.2005

Mahabad Petrochemical Company

Lying on an area of 202 hectares, Mahabad Petrochemical Co. will consist of a 300,000 tonne/year swing linear low-density polyethylene/high-density polyethylene (lldPE/hdPE) plant and a 30,000 tonne/year butene-1 unit. A consortium of Tecnimont of Italy and Nargan of Iran will contract the plants. The lldPE/hdPE facility will be based on Basell Spherilene technology and the butene-1 technology will be provided by Axens of France. The contract calls for the supply of process technologies, engineering equipment and materials, technical assistance during construction, commissioning and start-up. Nargan will supply part of the detailed engineering and locally made materials and equipment. Mahabad plant will consume 324,000 tonne/year of ethylene. It is entirely owned by Bakhtar.

NPC News Bulletin Nov.2004-No.57

NPC to invite tenders for Lorestan and Azerbaijan petchem plants

NPC has issued request for proposal to long-listed bidders for its Lorestan and Azerbaijan petrochemical plants. Bid documents for these two projects are being prepared. The Lorestan petrochemical project will consist of a 300,000 tonne/year swing linear low-density polyethylene (lldPE)/high-density polyethylene (hdPE) complex and a 30,000 tonne/year butene-1 plant. The Azerbaijan project will also have a swing lldPE/ hdPE plant and a butene-1 unit with capacities similar to the Lorestan project. The required ethylene feedstock will be supplied through a 1500km pipeline which extends from the Pars Special Economic/Energy Zone in Assaluyeh.

NPC News Bulletin Oct-Nov.2005

Lorestan Petrochemical Company

Lorestan Petrochemical Co. will consist of a 300,000 tonne/year swing linear low-density polyethylene/high-density polyethylene (lldPE/hdPE) plant and a 30,000 tonne/year butene-1 units. A consortium of Tecnimont of Italy and Nargan of Iran will build the plant. The contract calls for the supply of process technologies, engineering equipment and materials, technical assistance during construction, commissioning and start-up. Nargan will supply part of the detailed engineering and locally made materials and equipment. The lldPE/hdPE facility will be based on Basell Spherilene technology and the butene-1 technology will be provided by Axens of France. Lorestan Petrochemical Company will consume 324,000 tonne/year of ethylene. The facility is 100% owned by Bakhtar and will be built in an area of 128 hectares.

Iran's NPC to use Basell technology for two 300 kt/yr PE plants

Iran's Lorestan Petrochemical Co and Mahabad Petrochemical Co have selected Basell's Spherilene technology for new linear low density and high density polyethylene plants planned in Iran, Basell announced Friday. The two companies are affiliates of Iran's National Petrochemical Co.

Lorestan Petchem's 300,000 mt/yr plant will be built at Khoramabad, while Mahabad Petchem's 300,000 mt/yr plant will be built at Mahabad in Iran's West Azerbaijan province. Start-up was planned for 2008, Basell said in a statement. Italian engineering company Tecnimont was selected as the EP contractor for the new plants along with Iran's NARGAN.

The new plants will be part of NPC's 11th Olefin project. Ethylene feedstock will be supplied from an ethane gas cracker at Assaluyeh. A 1500 km pipeline will connect the cracker with five petrochemical sites located in Iran's western provinces. The 11th Olefin project also includes a 300,000 mt/yr HDPE plant based on Hostalen technology and a 300,000 mt/yr LDPE plant based on Lupotech T, both licensed by Basell.

NPC News Bulletin Dec.2004-No.58

NPC selects contractors for its HDPE plant in Kermanshah Province

NPC has awarded an engineering, procurement, construction and commissioning (EPCC) contract to a consortium of UHDE of Germany and Sazeh of Iran to build a high-density polyethylene (HDPE) plant at the province of Kermanshah in west of Iran. The contract covers provision of license, basic and detailed engineering, procurement & supply of equipment, construction, precommissioning, commissioning, start-up and test-runs. The facility will produce 300,000 tonne/year of HDPE with different grades. It will be based on the Basell technology advanced catalysts. The required ethylene feedstock for the project will be supplied through a 1500km pipeline which extends from the Pars Special Economic/Energy Zone in Assaluyeh. The plant is scheduled to be completed within 28 months. It will be implemented by Gharb Petrochemical Complex.

→ Kermanshah Polymer Company

NPC News Bulletin Oct-Nov.2005

Kermanshah Polymer Company

Kermanshah Polymer Company will produce 300,000 tonne/year of high-density polyethylene (hdPE) with different grades. It will be based on the Basell technology advanced catalysts. Kermanshah Polymer Company will consume 305,000 tonne/year of ethylene and 5,000 tonne/tear of butene-1 as feed. The latter will be supplied by Mahabad Petrochemical Co. The EPCC contract for the facility has been awarded to a consortium of UHDE of Germany and Sazeh of Iran. It covers provision of license, basic and detailed engineering, procurement & supply of equipment, construction, precommissioning, commissioning, start-up and test-runs. The plant is wholly owned by Bakhtar Petrochemical Co.

NPC News Bulletin Oct-Nov.2005

Gachsaran Petrochemical Company

Gachsaran complex is planned to produce 500,000 tonne/year of monethylene glycol (MEG), 50,000 tonne/year of diethylene glycol (DEG), 3,500 tonne/year of triethylene glycol (TEG). It will also yield 100,000 tonnes of high purity ethylene oxide (EO) per annum. Output from the plant will be used mainly in downstream units to be set up in the same location next to the ethylene glycol/ ethylene oxide facilities. The contract for Gachsaran project has been awarded to a consortium of Mitsui Engineering & Shipbuilding Co. (M.E.S.) of Japan and Petrochemical Industries Design & Engineering Co. (PIDEC) of Iran. It calls for the provision of license, basic and detailed engineering, procurement and supply of equipment, erection, construction, pre-commissioning, commissioning, start-up and performance tests. The plant will use the Shell Technology. Located near the city of Gachsaran in Kohgiloyeh-va-Boirahmad Province, Gachsaran covers an area of 160 hectares where the main process plant takes up 30 hectares of the total space. It is 100% owned by Bakhtar. The plant's feedstock includes 328,000 tonne/year of ethylene to be supplied from the West Ethylene Pipeline and 368,000 tonne/year of Oxygen to be supplied by Gachsaran complex.

presstv.ir 2007/4/10

Construction starts on petrochem unit

http://www.presstv.ir/detail.aspx?id=5526§ionid=351020103Iran has commenced construction of a major petrochemical facility slated to become one of the largest producers of ethylene in the country.

Construction of the Gachsaran Petrochemical Complex in Iran's Kohkiloyeh-Boyerahmad province began Monday with a launch ceremony attended by numerous officials.

Gholam-Hossein Nejabat, managing director of the National Iranian Petrochemical Company (NIPC), said that the $600 million project will encompass an area of 160 hectares and that the production capacity at the complex when completed will be one million tons of ethylene per year.

The ethylene will be used to feed petrochemical units in Boroujen, Dehdasht, Mamasani and Kazeroun, each of which will receive about 300,000 tons of ethylene a year from the complex.

Nejabat, who is also Iran's deputy minister of oil, estimated that the Gachsaran complex will also produce close to 90,000 tons of propane per year.

"The facility is established along the ethylene transfer pipeline in the west of the country. The unit is Iran's second largest unit after the Jam ethylene production complex and is projected to go online in 2010," he said.

The deputy minister expressed optimism that the project will help create jobs in the region and contribute to the nation's economic development within five years.

The city of Gachsaran, which sits in a major oil-rich region in the south of Iran, boasts a daily output of 750,000 barrels of oil.

plastemart.com 2007/4/9

Construction work for two petrochemical complexes to begin in Iran

The construction work on two petrochemical complexes at Gachsaran and Dehdasht is to commence in Iran. The two petrochemical plants are to be built along the ethylene pipeline earlier laid in western Iran.

The plant at Gachsaran will have a capacity to produce over one million tons of ethylene and propane. An estimated 1.3 million tons of ethane will be the feedstock requirement and will be supplied by Bidboland.

(* Bidboland gas refinery, near the city of Behbahan in Khuzestan province )

Upon completion, Dehdasht complex will produce 300,000 tons of heavy polyethylene and its 305,000 tons of required feedstock will be provided by the west ethylene pipeline and other petrochemical plants in the region.

The two complexes are scheduled to come on stream in 2010.