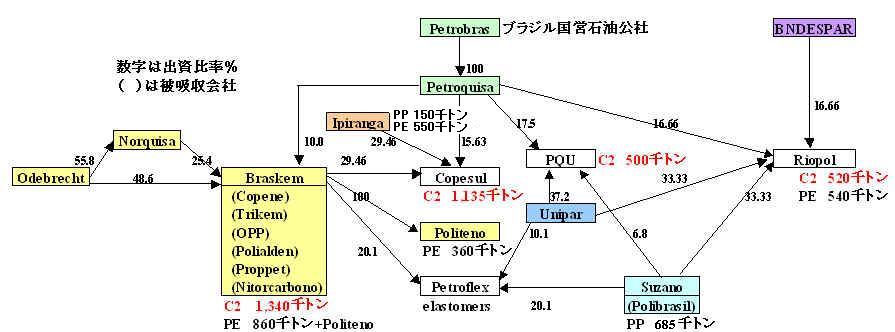

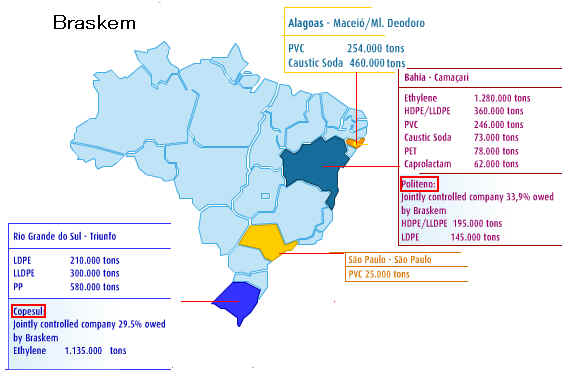

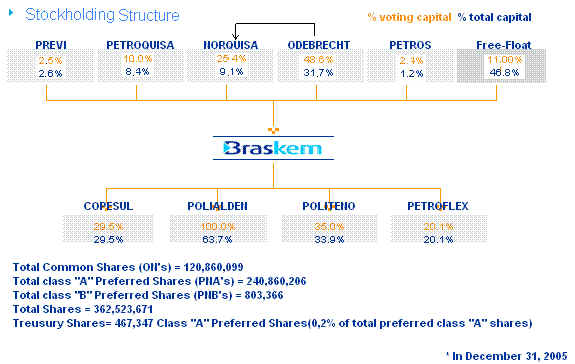

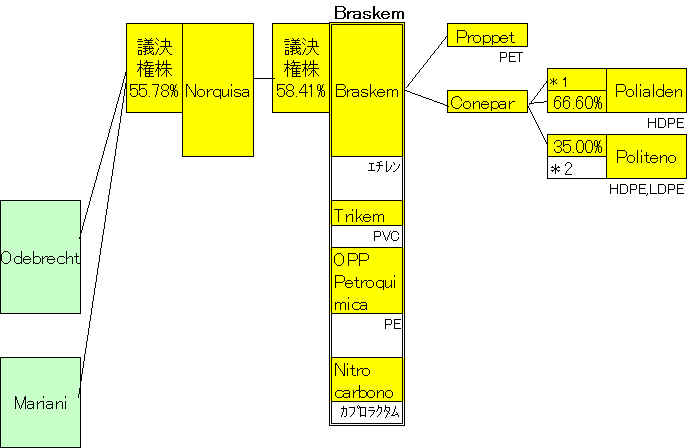

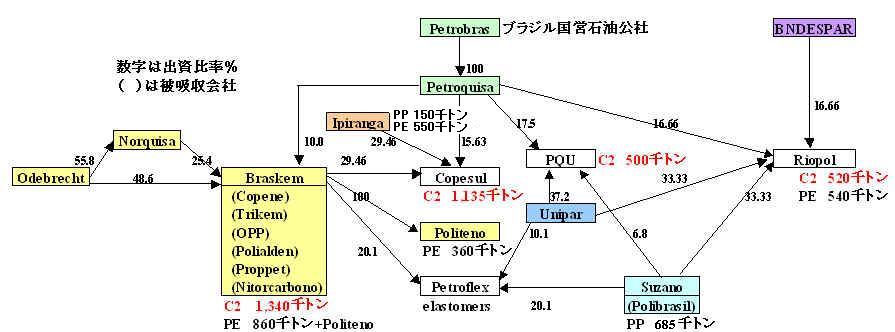

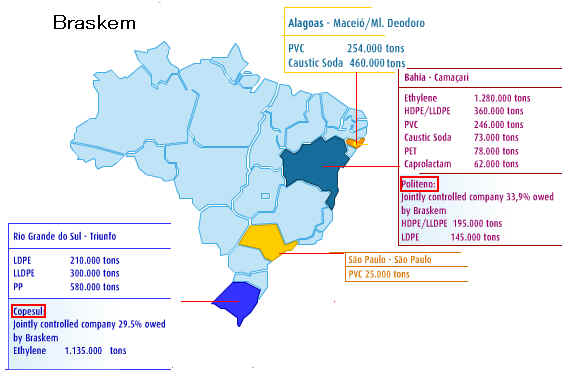

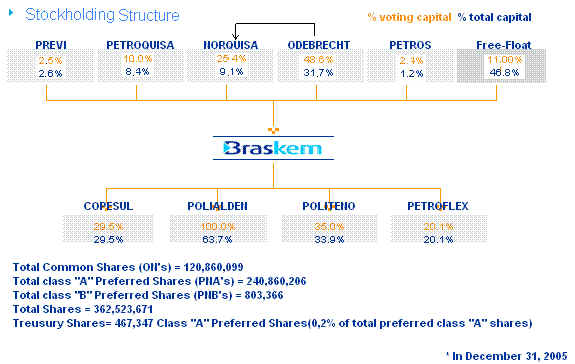

Braskem Politeno

OPP Polietilenos at

Triunfo manufactures polyethylene in two swing plants capable of

producing LLDPE and HDPE fromethylene supplied by COPESUL.

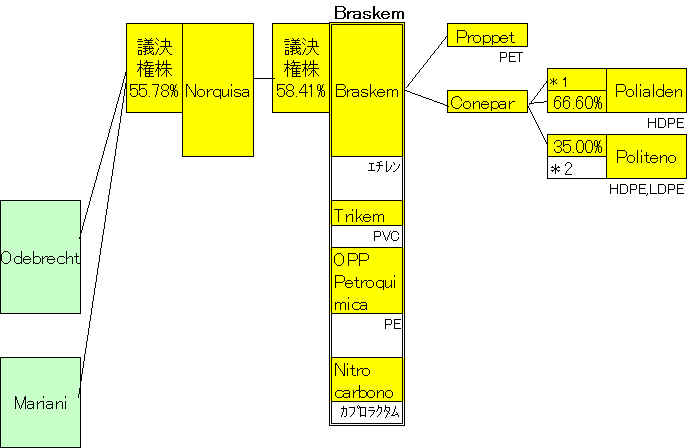

*1 Polialden HDPE 三菱化学、日商岩井が出資 → 両社株式売却

*2 Politeno

住友化学、伊藤忠が出資

*3 Ciquine 三菱化学、日商岩井が出資 → 両社株式売却

*4 BraskemがOPP,

Nitrocarbonoを吸収

*5 Trikem PVC 三菱化学、日商岩井が出資 → 両社株式売却

*6 BraskemがTrikemを吸収 (Odebrechtから分離)

Odebrecht/Mariani

がCentral BankからConepar株式63.82%を買収し、グループで100%保有

Copesul Located in Triunfo, a

county of the state of Rio Grande do Sul

Classified

as a large-size cracker, Copesul produces about 40% of ethylene consumed

in Brazil, nameplate capacity of 1.135

million

tons/year. Besides ethylene, its main product, Copesul

produces propylene, butadiene, benzene, toluene, xylenes,

MTBE, butene-1, propane, and others, a total of 3

million

tons per year of petrochemicals. More than 80% are consumed

in South Petrochemical Complex. Remaining products are sold

to other Brazilian states or exported.

Copesul was privatized

in 1992

|

| Ipiranga

Group |

29,46 % |

|

| Braskem Odebrecht

Group |

29,46% |

|

| Petroquisa |

15,63% |

|

| Others* |

25,45% |

|

| * Banks,

pension funds, other investors. |

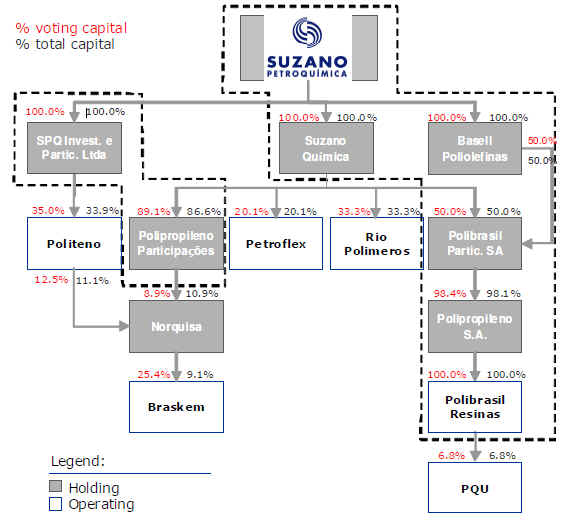

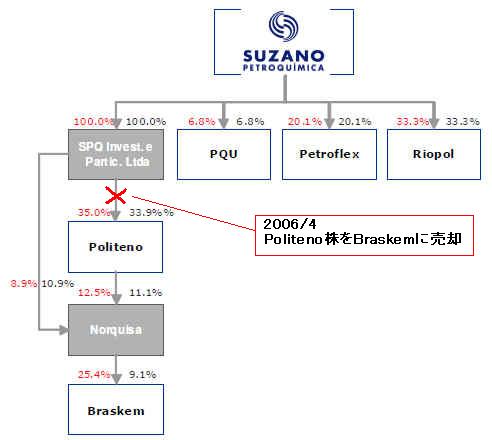

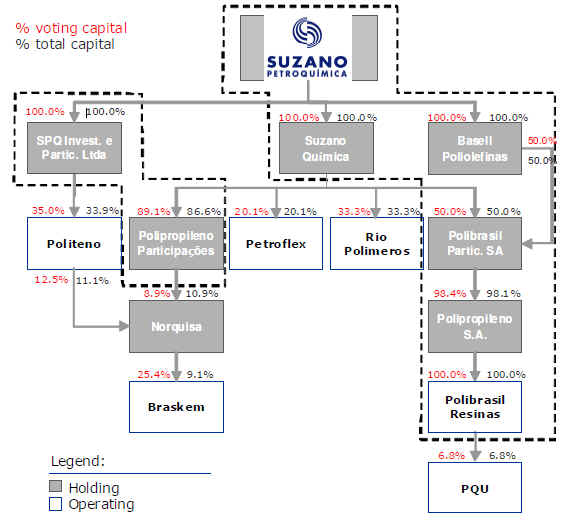

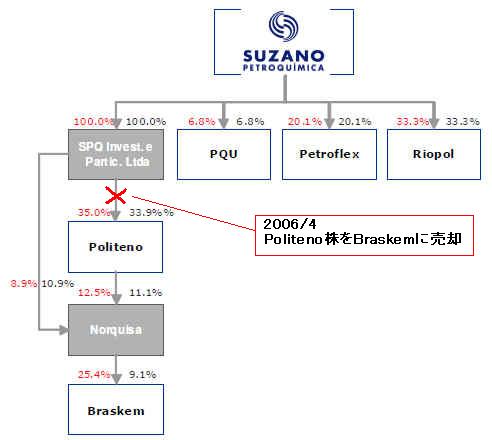

Suzano

Petroqui'mica

Latin American leader

in the production of polypropylene resins and the 2nd largest

producer of thermoplastic resins in Brazil.

The Company has a

production capacity of 625

thousand tons/year of polypropylene distributed within its

three facilities located in Maua (State of Sao Paulo),

Duque de Caxias (State of Rio de Janeiro) and Camacari

(State of Bahia).

2005/9/1 Polibrasil をBasell から買収

total production capacity

of 625 kton/year of polypropylene and 25 kton/year of

compound polypropylene. The agreement also

encompasses the simultaneous sale to

Basell of the totality of the polypropylene compounding

business of Polibrasil.

Facilities

(Polypropylene Resins) |

Installed

Capacity

(thousand ton/year) |

after

expansion

(thousand ton/year) |

Duque

de Caxias

|

200.0

|

300.0

|

Maua'

|

300.0

|

450.0

|

Camac,ari

|

125.0

|

125.0

|

Total

|

625.0

|

875.0

|

Suzano Petroquimica

is a joint controlling

shareholder of Riopol and Politeno, polyethylene producers, and Petroflex, synthetic elastomer producer;

both products are raw materials for the converters, as the

polypropylene (more details at Suzano´s Groups section).

Riopol http://www.chemicals-technology.com/projects/rio/

Riopol was created in

1996 to implement a grand project, the Rio de Janeiro

Gas-Chemical Production Complex, in the vicinity of the Duque

de Caxias refinery - Reduc, owned by Petrobras. The Complex

was inaugurated on 23 June, 2005 and is comprised of two units

- an ethane and propane pyrolysis unit, with installed

capacity of 520 thousand ton/year of

ethylene,

and another unit producing high density

(HDPE) and low density (LLDPE) polyethylene, with installed

capacity of 540thousand ton/year.

Rio Poli'meros'

Pyrolysis Unit has an annual production capacity of 520.0

thousand tons of ethylene and 75.0 thousand tons of

propylene.

Additionally, this unit has an annual production capacity

of 5.0 thousand tons of hydrogen and 33.0 thousand tons

of pyrolysis gasoline.

The Polymerization unit, on the other hand, has two

independent production lines with an annual capacity of 270.0

thousand tons of polyethylenes each, for a total annual

capacity of 540.0 thousand tons of polyethylene. This unit is of the

swing type, capable of producing LLDPE and HDPE. This

flexibility allows for adapting the product mix to the

needs of the market.

The Rio de Janeiro

Gas-Chemical Production Complex is the first Brazilian

petrochemical complex to use natural gas fractions as

petrochemical raw-material to manufacture ethylene and the

first integrated petrochemical project in Brazil, gathering

production units of ethylene and polyethylene.

The shareholders of Riopol are Suzano

Petroqui'mica (33,33%), Unipar (33,33%), Petroquisa (16,66%)

and BNDESPAR (16,66%).

PQU

PQU, Brazil's first

basic petrochemical products plant, was incorporated December

12, 1966 under the name Petroqui'mica Unia~o Ltda.,

From 1971 onward,

PQU's shareholder body was composed by 90% of

domestic capital, from Petrobras (Petroquisa 17.5%) and

Unipar(37.2%), a domestic private group(Suzano 6.8%), and 10%

of foreign capital, from companies such as

International Finance Corporation, Provident International

Corporation, Citicorp, and Venture Capital Ltd.

In November 1980, the

DBN I (Debottlenecking) project was completed, increasing

ethylene production from 300 thousand to 360 thousand tons

per year. now 500

Ipiranga

Ipiranga Petroquimica

produces four thermoplastic resins present in several

day-by-day products.

The High, Medium and Linear Low Density Polyethylenes (HDPE,

MDPE and LLDPE), besides Polypropylene (PP), are produced in

the five industrial plants in the Petrochemical Complex of

Triunfo-RS.

Ipiranga Petroquimica was founded in 1976 and it was first

called Polisul Petroquimica. Hoechst

(Germany), Petroquisa (state owned company) and Empresas

Petroleo Ipiranga (one of the largest private

company in Brazil) were the only Polisul shareholders.

It was in 1992 that Ipiranga and Hoechst bought

Petroquisa's shares, taking over the control of

Polisul. By that time, each shareholder had 50% of the

company.

By the year 1997, Hoechst shareholders decided to focus their

investments in science and health business. That was the

opportunity when Ipiranga bought Hoechst shares and the name Polisul

Petroquimica was changed to Ipiranga Petroquimica (now 100%

owned by Empresas de Petroleo Ipiranga).

The petrochemical site of Triunfo (South Brazil) has many

companies but Ipiranga was the first one to start up in 1982

(together with the cracker - COPESUL). It first began with a

HDPE 60.000 ton/year capacity.

In 1986, the industrial plant was debottlenecked in order to

produce 100.000 ton/year.

In 1990, a second industrial plant was built and it raised

the HDPE production capacity to 220.000 ton/year.

The third unit to start up was built in 1996, reaching

350.000 ton/year HDPE production capacity.

The 150.000 ton/year PP plant and the 150.000 ton/year

HDPE/LLDPE swing plant started producing in 1999.

In its Brazilian site (Triunfo), Ipiranga is able to produce 150.000

ton/year of PP, 400.000 ton/year HDPE and 150.000 ton/year

HDPE/LLDPE in its five (05) petrochemical units.

Unipar

The birth of UNIPAR

is entwined with the origin of the petrochemical industry in

Brazil, ? and consequently with an important part of the

country’s History.

When the Federal

Government opened up the importation and processing of crude

oil to private enterprise, Refinaria União was a pioneering enterprise

which, for two decades, became a landmark not only because it

processed 20,000 barrels per day and employed the most modern

technology in the sector, but especially because it trained

hundreds of high-level technicians in specialties that had

not existed in Brazil up to that time.

It was these new

professionals who employed all their knowledge in the

installation of the first Petrochemical Complex in Brazil, a

successful enterprise of the União Group, which would later

give rise to UNIPAR-União de Indústrias Petroquímicas S.A. With the inauguration of

Petroquímica União (PQU), in São Paulo, Brazil started

producing ethylene, propylene and other raw materials for

second generation industries. In addition to Petroquímica União(PQU), Poliolefinas,

Carbocloro, Empresa Brasileira de Tetrâmero, Brasivil-Resinas Vinílicas and Copamo-Consórcio Paulista de Monômero were part of UNIPAR’s very significant initial

assets.

Meanwhile, UNIPAR has

become a Group of ten distinct businesses and a listed

corporation, which, among other projects, is taking part in

the installation of the first Gas-Chemical Complex in Brazil:

Rio Polímeros, in Duque de Caxias,

State of Rio de Janeiro, which is expected to start up in

2004.

Carbocloro

Hydrochloric

acid, liquid chlorine, EDC, sodium

hypochlorite, caustic soda,

Petroflex BR、SBRほか

Polietilenos

Uniao EVA LDPE

Chevron Phillips

Chemical's proprietary loop slurry PE technology will be

employed in a new 200,000 metric tons per year reactor

that is part of Polietilenos Uniao's strategic PE

expansion at its plant in Santo Andre, Sao Paulo, Brazil.

The facility is expected to startup in 2007.

The new plant

which will produce HDPE/LLDPE and will go onstream by mid

2007, more than doubling Polietilenos União's PE capacity. (2005/1)

Petroquímica União PQU

Unipar's expansion project

is to increase the installed capacity of the ethylene

plant at subsidiary Petroquimica Uniao (PQU) by 200,000

tons a year (t/y) to 720,000t/y.

The expansion would

reportedly need 350,000t/y of gas and 200,000t/y of

naphtha, which Petrobras should be able to provide from

its Recap (Capuava) and Revap (Henrique Lage) refineries.

Rio Polímeros Piopol

| Company |

Main

Products |

Final

Uses |

UNIPAR

Chemical Division |

Cumene

Olefins

Isoparaffins |

Resins and Fibers

Industrial Detergents

Solvents |

| Polietilenos União |

LDPE

EVA |

Plastic Packages and

Articles

Footwear |

| Petroquímica União |

Ethylene

Propylene

Benzene

Butadiene

Orthoxylene

Gasoline |

Plastics and Resins

Resins and Fibers

Fibers and Anhydrides

Rubbers

Anhydrides and Plasticizers

|

| Carbocloro |

Chlorine

Soda

EDC |

Water treatment and in

the Chemical, Steel, and Pulp & Paper Industries

PVC |

| Petroflex |

Synthetic Rubbers |

Tyres

Rubber Articles |

| Polibutenos |

Polyisobutenes |

Lube Additives |

| Rio Polímeros |

LLDPE

HDPE |

Plastic Packages and

Articles |

Petroquisa Petrobras Quimica S/A

Petrobras

Exploration & Production

Natural Gas

Energy

Refining

Transportation and Storage

Distribution

Petrobras Quimica S.A - Petroquisa

PETROQUISA, Petrobras subsidiary, was incorporated by Decree

no. 61.981, dated December 28, 1967, to develop and

consolidate the chemical and petrochemical industry in

Brazil. The purpose of the company is to participate in

companies operating in the manufacture, trade, distribution,

transportation, import and export of chemical and

petrochemical products, in general. Moreover, it can perform

all the aforementioned activities directly. After its

incorporation, three petrochemical complexes

were built - in Sao Paulo, Bahia and Rio Grande do Sul.

PETROQUISA is present in the three Brazilian petrochemical

centers, through its holdings in BRASKEM,

Petroquimica Uniao (PQU), and COPESUL, companies responsible for the

production (from naphtha, a petroleum byproduct feedstock for

the petrochemical industry) of basic petrochemical products

(ethylene, propane, benzene, etc), feedstock for second

generation plants to manufacture other products (plastics,

rubber, etc.) used by state-of-the-art industries in

manufacturing articles for public consumption (packaging,

tires, etc.).

PETROQUISA also has interest in six other operational firms,

as well as in Rio Polimeros S.A., affiliate responsible for

the Rio de Janeiro Chemical Gas Complex, a project under

construction next to Duque de Caxias refinery in Rio de

Janeiro.

| COMPANY |

PRODUCT |

VOTING

CAPITAL% |

TOTAL

CAPITAL% |

| Braskem S.A.

|

Basic,

intermediate and fi nal petrochemicals |

10.0 |

8.4 |

| Cia.

Petroquimica do Sul - Copesul |

Basic

petrochemicals |

15.6 |

15.6 |

| Petroquimica

Uniao S.A. |

Basic

petrochemicals |

17.5 |

17.4 |

| Metanol do

Nordeste - Metanor S.A |

Methanol |

49.5 |

33.4 |

| Deten

Quimica S.A. |

Linear

alkylbenzene |

28.6 |

27.5 |

| Fabrica

Carioca de Catalisadores S.A. |

Catalyzers |

50.0 |

50.0 |

| Petrocoque

S.A. Industria e Comercio Calcinated |

petroleum

coke |

35.0 |

35.0 |

| Petroquimica

Triunfo S.A. |

Low density

polyethylene |

70.5 |

85.0 |

| Rio

Polimeros S.A. (Riopol) |

Polyethylene |

16.7 |

16.7 |

Petroquimica

Triunfo

In

May, Petroquisa exercised its preemptive right to acquire the

shares held by Primera (part of the Dow-Quimica group) in

Petroquimica Triunfo’s capital. On

the conclusion of this operation, Petroquisa’s stake in the

voting capital was increased from 45.22% to 60.63% and

corresponding to 80.07% of Petroquimica Triunfo’s total

capital. Petroquisa disbursed approximately US$ 25.5 million

for this additional stake.

Subsequently, Petroquisa acquired the remainder of Primera’s stake in the

company given that the other partner, petroplastic, decided

not to exercise its preemptive rights.

As a result, Petroquisa’s final

participation in the company was increased to 70.45% of the

voting capital and to 85.04% of the total capital, the

company disbursing a further US$ 32 million.

Rio

Polimeros S.A. (Riopol) a company owned by Suzano

(33.3%), Unipar (33.3%), Petroquisa (16.7%) and BNDESPar

(16.7%), is concluding the construction of a new

petrochemicals plant in Duque de Caxias, state of Rio de

Janeiro.

With operations scheduled to come on stream in the fi rst

half of 2005, Rio Polimeros will have an annual production of

515 thousand tons of polyethylene with various specifications

and 76 thousand tons of propene, using as raw materials

ethane and propane extracted from Campos Basin natural gas.

The total investment is estimated at US$ 1 billion

BNDESPAR.

Banco

Nacional de Desenvolvimento Economico e Social Participacoes

the private-sector

investment arm of Brazil's National Development Bank, BNDES,

Petroflex Duque de Caxias (RJ), Triunfo (RS)

e Cabo (PE)

Largest producer

in Latin America, and sixth in the world, Petroflex holds

today approximately 80% of market share in the Brazilian elastomers market. It has 3

industrial units: Duque de Caxias, State of Rio de

Janeiro; Triunfo, State of Rio Grande do Sul and Cabo,

State of Pernambuco, all certified by ISO 9001, ISO 14001

and OHSAS 18001 standards, amounting to a total installed

capacity of 410 thousand ton/year. Petroflex exports

approximately 30% of its production to over 70 countries.

Petroflex

offers more than 70 types of elastomers produced with

raw materials from oil byproducts. Its products

include synthetic ESBR, SSBR and BR rubbers,

thermoplastic TR rubber, synthetic latex, PBLH and

nitrilic NBR rubbers.

| Units |

Installed

Capacity

(thousand tons/year) |

Duque de

Caxias

|

210.0

|

Triunfo

|

76.0

|

Cabo

|

125.0

|

Total

|

411.0

|

Created by

Petrobras in 1962, Petroflex was the first petrochemical

company to be privatized in Brazil, in 1992, as part of

the National Privatization Program (PND). Petroflex is controlled

by Suzano Petroqui'mica(20.1%), Braskem(20.1%)and

Unipar(10.1%),

which hold, together, 50.3% of the total capital.

March 31, 2014

Synthos announces its plan to invest

in Brazil

Synthos S.A. is planning

to build a neodymium polybutadiene rubber plant in Triunfo Petrochemical

Complex in Rio Grande do Sul.

Synthos

S.A. is planning to build a

neodymium

polybutadiene rubber plant in

Triunfo Petrochemical Complex in Rio

Grande do Sul. The investment

will be carried out provided that the

2013 contracts on raw material supplies

will come into effect.

Upon the implementation of those

contracts, the company will build a

modern production plant producing

neodymium polybutadiene rubber (NdBR)

used to manufacture high-performance car

and truck tires and various technical

rubber products. The plant capacity will

reach 80,000

tonnes per year, which will

result in a huge production growth of

elastomers in Brazil and will replace a

significant part of the current import.

“Considering the growing demand for

synthetic rubber in Brazil and other

South American countries, we will not

aim at replacing the local production,

but try to substitute the import into

the region,” said Tomasz Kalwat,

CEO, Synthos S.A.

The production of polybutadiene rubber

in Brazil will be based on the

license granted by Michelin.

2013/6/26

Michelin とChandra Asri 、インドネシアに合成ゴム製造JV設立

Synthos has signed contract agreements

with tire manufacturers Michelin and

Pirelli regarding the

supply of NdBR to their facilities in

Brazil.

The time remaining until the

implementation of contracts will be

dedicated to the preparation of the

necessary documentation (including

project documents) without incurring

substantial financial liabilities.

Brazil is the world’s seventh economy

and the largest economy in South

America. It is one of the emerging

markets with high growth potential.

Synthos S.A. continuously emphasises its

presence on that market. In 2012, our

rubber export to South America amounted

to 3.3%, and in 2013 it reached 6.3%.

According to the Polish Foreign Market

Research Lab, in the first three

quarters of 2013, the sales of tires for

new cars in Brazil increased by 9%. The

replacement tires market increased by

11% as compared to the previous period.

Thus, the Brazilian market and other

South American economies are highly

attractive.

ーーーーーーーーー

Synthos

S.A. is one of the largest manufacturers of chemical raw materials

in Poland, as well as being Europe’s

No. 1 manufacturer

of rubber emulsions and third largest manufacturer of polystyrene for foaming

applications. Synthos S.A. was established on the basis of Firma Chemiczna Dwory

S.A. and Kaucuk a.s.

旧称 Dwory で、チェコのKaucuk買収後、改称した。

October 5th, 2008 -

Dwory S.A. sign a licensing contract with the

Michelin company for the purchase of polybutadiene

rubber production technology.

At the same time, a commercial contract for deliveries of this type of

rubber to Michelin is signed for a period of at least seven years from the

start of production. Polybutadiene rubbers produced according to the

neodymium technology purchased from Michelin

are among the newest generation of rubbers used to produce tires with

improved safety standards, including tires made for higher speeds.

October 23rd, 2007 – The

Chemical Company changes its name to Synthos S.A.

The assumption of a new name is an effect of organizational changes

related to the finalization of the acquisition process

of the Czech company, Kaucuk a.s.

SynthosRubbers

Synthos S.A. is one of the

world’s largest manufacturers of synthetic rubber. The company is

the largest European manufacturer of styrene butadiene rubber (ESBR),

and also offers neodymium polybutadiene rubber (NdBR), the

production of which started in 2011, and high styrene rubber (HSR).

In 2012, a contract was signed with Goodyear for the license of

production of solution styrene butadiene rubber (SSBR) to start in

2015. The NdBR and SSBR rubber is used for production of

high-performance tires, so called green tires.

Production of

NdBR polybutadiene rubbers begins in

the III quarter of 2011 in Kralupy. Production is carried out using

a neodymium catalyzer. Production capacity amounts to 80 thous. tons

per year.

In June, 2012, a licensing

contract is signed with The Goodyear Tire &

Rubber Company, the object of which is for Goodyear to grant

access to advanced SSBR rubber

production technology. The start-up of a production unit operating

based on the acquired technology is planned for 2015.

In 2013, The construction of the SSBR rubber installation is started

at Synthos Dwory. The cost of the investment will amount to 568 mln

PLN, out of which 147 mln PLN will constitute financing from EU

funds.

SynthosEPS

Synthos S.A. is

a leading producer of

EPS in Europe.

Expandable polystyrene (PS-E or EPS) is a polymer compound

containing pentanes allowing expansion. EPS may contain

additives enhancing the processing or giving the foam

specific properties. These are fire-retardants, agents

reducing heat transfer and water absorption, external

lubricants for enhanced processing, colourants etc.

SynthosXPS

押出 発 泡 ポリスチレン

The XPS extruded

polystyrene is characterised by very good thermal

insulation, resistance to humidity impact and high strength.

Based on its long-time experience in the field, Synthos S.A.

has created an entirely new product – Synthos XPS, based on

extruded polystyrene.

Synthos XPS is a

homogeneous construction material, characterised by a smooth

surface and a structure made of small, closed cells. This

structure makes it an ideal product for numerous

heat-insulating applications.

SynthosPS

Polystyrene products delivered

under the trade name SYNTHOS PS are manufactured in the continuous

block polymerisation process at Synthos Dwory and SYNTHOS Karlupy

a.s. in the Czech Republic. Synthos S.A. manufactures and offers

polystyrene of high quality and stability.

SynthosSpecialties

OSAKRYL®, WINACET®

are market brands of water dispersions produced by

Synthos S.A. The Winacet® group includes mostly

vinyl acetate-based dispersions, while the Osakryl®

group includes acrylic and styreneacrylic products

as well as acrylic monomer copolymers with other

monomers. At present, the portfolio of Synthos water

dispersions satisfies the needs of broadly

understood construction chemicals manufacturers,

i.e. manufacturers of paints, plasters, primers,

putties, including decorative putties (stucco),

adhesives and many other products.

SynthosAdhesives

Synthos Adhesives is a

division of Synthos S.A., the leading European manufacturer

of chemicals.

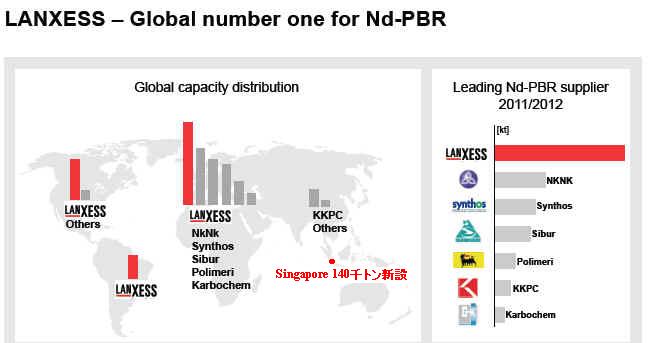

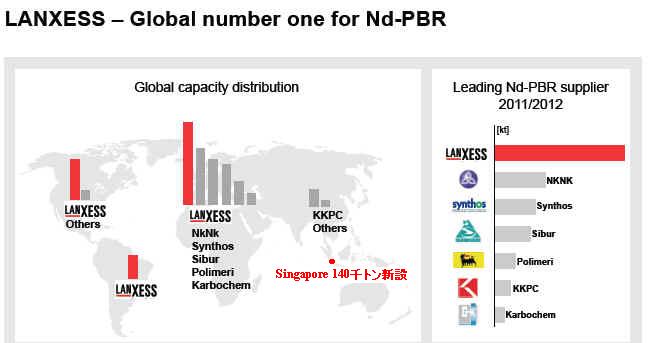

NKNK(Nizhnekamskneftekhim)

is one of the biggest producers and exporters of petrochemical products

in the Russian Federation.

KKPC:Kumho

Petrochemical

SIBUR Group

はGAZPROMが100%出資するロシア最大の垂直統合石油化学会社

Polimeri Europa:ENI

100%

Karbochem

(Pty) Ltd is a South African manufacturer of various types of synthetic

rubber