トップページ

DuPont http://www.dupont.com/

Dioxin

裁判

C8問題

Presentation by Chad

Holliday, Chairman & CEO of DuPont

E.I.デュポン・ドゥ・ヌムール&カンパニー(E.

I. duPont de Nemours & Company Inc.)

1802年 創立

1903年 中央研究所を開設

合成ゴム「ネオプレン」、合成繊維「ナイロン」を発明

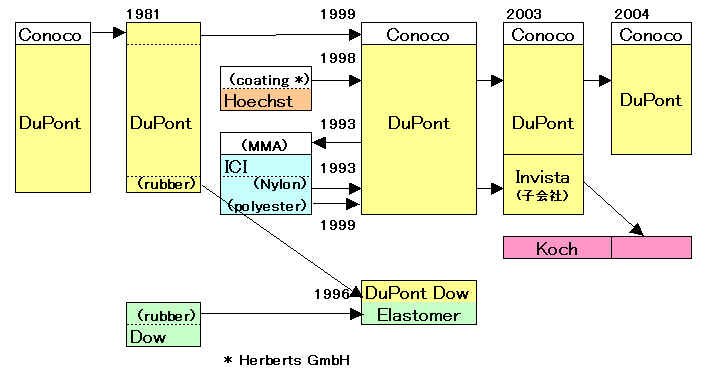

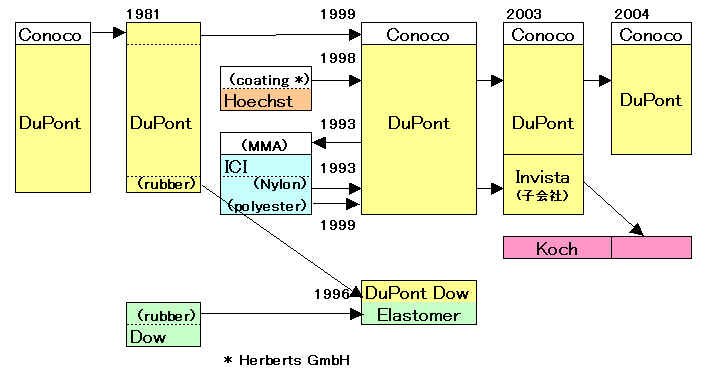

81年 石油会社コノコ社を吸収合併

86 シェルの農薬事業買収

93年 自社のアクリル事業と英ICI社のナイロン事業をスワップ

94年 カナダのLLDPE事業をノバ・コア社に売却

96年 エラストマー事業をダウケミカルとのJV「デュポン・ダウ・エラストマー」に移管

97年7月 ICIの全世界のポリエステル事業(ポリエステルフィルムおよび同レジン、高純度テレフタル酸)と関連技術および北米を除く酸化チタン事業を買収することで合意

ポリエステル事業は99年2月にICIからの事業買収

酸化チタン事業の買収中止

99年3月 塗料メーカー・ハーバーツ社の買収完了(自動車塗料分野で世界最大)

2000年1月 ポリエステルフィルム事業で帝人と合弁会社を設立

99年7月 コノコとの間で株式交換、デュポン本体から切り離し

(コノコのB種普通株式とデュポンの普通株式を2.95:1の割合で交換)

In 2001 DuPont

announced it would sell its

pharmaceutical business to Bristol Myers Squibb.

イーストマン社から高機能結晶性プラスチックス事業を取得

デュポン製品の日本国内生産/加工状況

DuPont and Bunge Announce

Global Alliance,

Including

Joint Venture to Produce and Market Specialty Food

Ingredients

デュポン 買収で知的財産強化

繊維部門売却交渉 DTI Inks Strategic

Alliance with Huvis

Negotiations With

Koch Industries

デュポン

テキスタイル アンド

インテリア、社名を「インビスタ」に変更

インビスタ、中国社に1.4BD技術を供与

DuPont

and Koch Subsidiaries Agree On Sale of INVISTA Fibers

Unit

Koch Subsidiaries Buy Fibers

Unit from DuPont → 新インビスタ

DuPont Performance Coatings to

Expand Business in China

DuPont Increases Equity

Position and Outlines Investment Plans For Automotive

Coatings in China

DuPont Fluoroproducts Announces

Land Reservation in China

DuPont to Locate Asia Pacific

Research & Development Center in Shanghai

DuPont Takes Actions to Achieve

USD 900 Million Annualized Cost Improvement in 2005

World-scale PBT plant by DuBay

Polymer GmbH (jv of DuPont and Bayer)

DuPont Announces Organizational

Alignment to Drive Growth

中国を拠点とするソリッドサーフェス(人工大理石)メーカーの買収を発表

DuPont Inaugurates Corian® Plant in Korea

米国デュポン社、中国での特殊製品群の生産能力を拡大

DuPont and Tate &

Lyle Form Bio-Products Joint Venture

DuPont Acquires BioSentry's Animal

Health Business Assets

DuPont Completes Purchase

of Maxygen Subsidiary Verdia

デュポン、テフロン「有害物質使用」で米環境保護局と対立

DuPont Opens $130 Million Facility

to Produce Innovative Nonwoven Fabrics

Sabanci Holding to

Acquire DuPont's Share of DuPont Sabanci Polyester

(Europe)

DuPont

Dow Elastomers 解散

DuPont Dow Elastomers、DuPont

Performance Elastomersに

DuPont Announces Research

Agreement with India's National Chemical Laboratory

Dupont decided world scale

TiO2 project in Shandong

US DuPont says it will

not give up the titanium dioxide project in Dongying

City of Shandong Province

DuPont and Lucite announce

agreement regarding acrylonitrile operation at Beaumont

デュポン、ナイロン樹脂、ポリイミド樹脂の生産拠点をシンガポールに建設

2006/6 BP and

DuPont Announce Partnership to Develop Advanced Biofuels

2006/6 DuPont to

Produce New High-Performance Polymers Made with Renewable

Resources

2006/10 DuPont

Partners with Zhangjiagang Glory Chemical Industry Co. to

Produce First Bio-Based DuPont Sorona® Polymer in

Asia

2006/11 DuPont

Tate & Lyle Bio Products Begin Bio-PDO Production in

Tennessee

2007/6 DuPont Tate & Lyle

Joint Venture Officially Opens $100 Million Bio-PDOTM Facility

2006/12 DuPont

Agriculture & Nutrition Increases Investment in Plant

Biotechnology

2007/3 DuPont, Honeywell Announce

Refrigerants Agreement

2007/8 DuPont Settles Patent

Infringement Case Against Chinese Company

DuPont

to provide next-generation dental monomer technology to

GC Corporation of Tokyo

DuPont expands nylon resin

compounding in Korea

2007/9

DuPont

Plans $500 Million Expansion for Kevlar®

Sinopec in EVA joint

venture with DuPont

2007/10 DuPont ordered to provide

medical monitoring in Harrison County

2008/2 Judge

Upholds $196.2 Million Award Against DuPont

DuPont

Announces Nanotechnology Alliance that Combines the

Best of Polymers with the Best of Metals

2007/12

DuPont Forms Joint Venture

with Chinese Biotech Firm

DuPont Selects South

Carolina Site To Expand Production of High-Performance

Kevlar®

Fiber

2008/2

DuPont Opens PTFE Plant in

China

DuPont Acquires Chemtura

Fluorine Chemicals Business

2008/5

DuPont Invests $150

Million in Key Growth Markets for Ethylene Copolymers

DuPont,

Genencor Create Cellulosic Ethanol Company

2008/7 DuPont to Add Capacity for

Engineering Resins in China

2008/9 DuPont’s

Board of Directors Appoints Ellen J. Kullman President

and Board Member

2009/1 DuPont's Swift Response to the

Financial Crisis

2009/8 DuPont、成長路線へ組織簡素化

2009/10 DuPont sees return to '08

profit levels in '12

DuPont’s

Board of Directors Appoints CEO Ellen Kullman Chair

2009/11 CEO Ellen J. Kullman

インタビュー 「化学」から「科学」の会社へ

2010/2 セルロース系エタノールの高性能生産施設がオープン

2010/8 DuPont suspected of

anti-competitive behavior

2010/9 DuPont and Sinopec start

EVA production in Beijing

INVISTA and DuPont Settle

Lawsuits

2010/11

DuPont

Reaches Agreement to Settle Spelter Lawsuit

2011/1 DuPont announces binding

offer for Danisco

2011/5 DuPont Announces Global

Plans to Expand Titanium Dioxide Capabilities

DuPont

Successfully Completes Tender Offer for Danisco

2011/7

DuPont Expands in Solar Energy with

Acquisition of Innovalight

2011/9

DuPont Wins

$920Million Award in Kevlar Case

2011/10

DuPont Starts

Up $500 Million Kevlar® Facility in South Carolina

DuPont Said to

Seek Buyers for Teijin Venture, Powder Paint Unit

2012/2

DuPont and Yingli

Green Energy Enter $100 Million Strategic Agreement

2012/5

DuPont

Acquires Full Ownership of Solae

2012/8

DuPont

wins 20-year ban on Kolon's Kevlar rival

The Carlyle Group to Buy DuPont

Performance Coatings Business for $4.9 Billion

History

and Strategy

http://www.corporatewatch.org.uk/profiles/dupont/dupont.htm

An explosive

beginning

E.I. du Pont de Nemours and Company was founded in

1802 on the banks of the Brandywine River near

Wilmington, Delaware in the US.

The 1920s

also saw DuPont acquire General Motors, and enter into a

50-50 joint venture with Standard Oil (now known as

Exxon) to produce and market the lead additive in

petrol (known as ethyl). The new company was called

the Ethyl Corporation..

Economically, the company’s most important

discovery was Nylon.

The 2nd World War - making a killing (again)

World War 2 brought even more profits for DuPont.

1945-1980: the rise and fall of fibres

The post-war years brought further discoveries for

DuPont, including Mylar (a strong plastic film),

Dacron polyester, Orlon (a bulky acrylic fibre) and

Lycra.

Diversification in the early 1980s

Since DuPont was completely reliant on petrochemicals

to produce the vast majority of its products, in 1981

the company purchased the

petroleum company Conoco.

In the 1980s

DuPont began to reduce its dependence on synthetic

fibres, beginning with the purchase of Remington

Arms (a

manufacturer of sporting firearms and ammunition).

The 1980s

also saw DuPont branch out into the life sciences.

Maximising profits in the late 1980s

The early 1990s - further streamlining

DuPont entered into a pharmaceutical joint

venture with Merck. DuPont later acquired Merck’s share of the venture in

1998.

In 1993 the company sold its Remington

Arms business. It also sold

its acrylic business to ICI and in turn bought ICI’s

nylon business and later its worldwide polyester

films, resins and intermediates business.

The late 1990s - DuPont goes GM

In 1999 DuPont shed its Conoco

subsidiary, using the money to invest in

its growing biotech business by assuming 100%

ownership of Pioneer.

In 2001 DuPont announced it would sell its pharmaceutical

business to Bristol Myers Squibb.

1999/8/9

Statement by

Archie W. Dunham Regarding Conoco Split-off from DuPont

Conoco

President and CEO Archie W. Dunham issued the

following statement regarding the completion of

Conoco’s split-off from DuPont:

DuPont Buys

Conoco:1981

When DuPont bought petroleum manufacturer Conoco,

Inc. in 1981, it was the largest merger in corporate

history. The purchase gave DuPont a secure source of

petroleum feedstocks needed for many of its fiber and

plastics operations. Conoco also manufactured

profitable commercial petroleum products and coal,

produced by the wholly owned subsidiary Consolidated

Coal Company. DuPont sold all of its Conoco shares in

1999 in order to free up capital for investment in

other businesses.

|

Polymers engineered for

packaging professionals

Appeel® lidding resins

As a seal layer in flexible

lidding and labels, Appeel lidding sealant resins offer

controllable heat-seal strengths for easy, clean peeling when

used on CPET, APET, PP, polystyrene, PVC and PE rigid

containers. Appeel resins seal over a wide temperature range,

for easy processing with a variety of substrates including

foil, OPP, OPET and paper.

Biomax® resins

DuPont scientists have

created a new family of highly versatile polymers based on

polyethylene terephthalate (PET) technology and known

commercially as DuPont Biomax hydro/biodegradable polyester.

Depending on the application, up to three proprietary

aliphatic monomers are incorporated into the polymer.

Bynel® adhesive resins

Bynel adhesive resins create

a strong, interlayer bond between dissimilar materials in

multilayer films, tubes and other packaging and industrial

structures. Bynel can be coextruded or extrusion coated onto

a variety of structural, barrier or heat-seal materials.

DuPont offers the industry's widest range of standard and

custom formulations to meet a variety of high-performance

adhesion needs.

Conpol® additive resins

Conpol additive resins,

supplied in pellet form, are designed to modify the surface

properties of films or coatings of Surlyn ionomer resins and

Nucrel acid copolymer resins. They are concentrated

masterbatch products and should not be used by themselves in

extrusion equipment, but blended with the resin to be

modified.

Crystar® specialty polyester resins

DuPont tailors Crystar

specialty polyester resins to meet unique customer needs. A

flexible manufacturing process allows DuPont to introduce

comonomers and additives to customize resin properties such

as melt and flow points, intrinsic viscosity (IV), color and

diethylene glycol (DEG) levels.

DuPont 20s

polyethylene

The DuPont 20 Series resins

enjoy a specialized role in health care, cosmetic and food

packaging applications. These high-quality, low-density

polyethylene resins offer outstanding purity, consistency and

environmental stress crack resistance, as well as design and

decorating flexibility. Uses include injection blow molded

bottles, injection molded closures, and extruded tubing.

DuPont maintains pertinent information about its 20 Series

resins in FDA Drug Master Files.

Elvaloy® AC acrylate copolymers

Elvaloy AC acrylate

copolymers are a new family of butyl-, ethyl-, and

methyl-acrylate (EBA, EEA and EMA) resins that can be

processed easily on conventional extrusion and extrusion

coating equipment used by packaging film converters.

Elvanol® polyvinyl alcohol (PVOH)

Elvanol polyvinyl alcohol

(PVOH) is used in the manufacture of spiral wound tubes,

coated paper and specialty water-soluble films.

Elvax® EVA ethylene vinyl acetate copolymer

resins

Elvax EVA ethylene vinyl

acetate copolymer resins are available from DuPont in a wide

range of packaging film and coating grades. Elvax combines

tough, low-temperature sealability with excellent clarity,

cling, flexibility, impact and puncture resistance. Its easy

processability at low temperatures results in energy savings

and trouble-free processing.

Nucrel® acid copolymer resins

Nucrel acid copolymer resins

provide excellent adhesion to aluminum foil, nylon, paper,

and other polar substrates. As a seal layer in laminated and

coextruded structures, Nucrel resists delamination and seal

failure even in harsh environments. It has excellent hot tack

strength, low seal initiation temperature and good toughness.

Selar® PA amorphous nylon barrier resins

Selar PA amorphous nylon

barrier resins provide unique oxygen barrier properties when

wet or chilled, making the resins a perfect choice for

flavorsensitive refrigerated foods and beverages. In bottles,

jars and other rigid structures, Selar PA offers the crystal

clarity of glass, but with lower weight and better impact

resistance. Selar PA can be blended with nylon 6 and with

EVOH to provide certain property and processing advantages.

DuPont Selar® PT specialty polyester resins

DuPont Selar PT specialty

polyester resins offer excellent aroma and flavor protection,

good chemical resistance, and PET recyclability potential.

Properties include toughness, high melt strength, low

coefficient of friction and high temperature resistance.

Selar PT resins are sold for applications in blow molding,

sheet extrusion, cast and blown film, extrusion coating and

foam extrusion. End use markets include films for snacks and

lidding; bottles for cosmetics, personal care, juices and

condiments; trays for bakery, deli and dual ovenable

applications; and coated board for frozen entrees and juice

cartons.

Surlyn® resins

Tough, crystal clear Surlyn

resins offer the best seal integrity in the packaging

industry. Outstanding hot tack strength and high melt

strength, plus the industry's broadest sealing range, make

Surlyn the relied-upon choice for reducing leakers, improving

packaging speeds, sealing through contaminants, and boosting

efficiency. The sparkling clarity, high gloss and film

handling advantages of Surlyn also make it a proven leader in

visual carded display packaging.

日本経済新聞 2003/2/11

米大企業再生 デュポン 買収で知的財産強化

デュポンの事業再構築(1997年以降、単位億ドル)

| 売却・分離 |

買収 |

| ・石油大手コノコ(1997年) |

220 |

| |

|

| ・医薬品部門(2001年) |

178 |

| |

|

| ・繊維部門(2003年中) |

未定 |

|

・大豆たんぱく会社プロテイン・

テクノロジー(1997年) |

15 |

・英ICIのポリエステルフィルム

部門(1998年) |

30 |

・医薬品合弁の米メルク持ち分

(1998年) |

26 |

・独ヘキスト傘下の塗料会社

(1999年) |

19 |

・種子会社パイオニア・ハイブ

レッド(1999年) |

77 |

・有機ディスプレー会社ユニアッ

クス(2000年) |

10 |

| |

|

|

|

|

|

2003/3/6 デュポン

米国デュポン社、

イーストマン社から高機能結晶性プラスチックス事業を取得

http://jp.dupont.com/jpcorp/news/03-3-6EPEastman.html

米国デュポン社エンジニアリング・ポリマー事業部は、3月5日イーストマン・ケミカル・カンパニー社より、高機能結晶性プラスチック事業を取得したことを現地において二社合同で発表しました。

このビジネス・セグメントには、イーストマン社の液晶ポリマー(LCP)樹脂タイタンTM(TitanTM)

、ポリシクロへキシレン・ジメチレン・テレフタレート(PCT)樹脂サーミックス®(Thermx®)、および自動車、電気・電子、その他の産業で使用される強化PET樹脂、熱可塑性ポリエステル樹脂のサーミックス®EG

(Thermx® EG)シリーズが含まれます。

2003/4/14 DuPont

DuPont in Negotiations With Third

Party On Possible Sale of DuPont Textiles & Interiors

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/content/US/en_US/news/releases/2003/nr04_14_03.html

DuPont today announced that

it is in negotiations with a third party regarding the

possible sale of DuPont Textiles & Interiors (DTI). This disclosure is required to be

included in the offering circular for DuPont's tender offer

for the 24 percent of DuPont Canada stock that it does not already own.

The offering circular will be issued April 17.

DuPont continues to consider

all options to separate DTI, including an Initial Public

Offering (IPO). In February 2002 DuPont announced its

intent to separate DTI by the end of 2003, market conditions

permitting. All activities required to execute such a

transaction remain on their scheduled timeline.

DuPont Textiles &

Interiors

DuPont Apparel &

Textile Sciences

Lycra® Brand Fiber(ポリウレタン弾性繊維), Terathane® Intermediates

DuPont Nylon

DuPont

Flooring, Intermediates, Specialties & Polymer

DuPont Polyester

Fibers, Resins

& Intermediates

DuPont Canada

http://ca.dupont.com/NASApp/dupontglobal/ca/index.jsp

DuPont Canada Inc., whose

business origins in Canada date to 1877, is a diversified

science company. The wide range of products sold includes

nylon industrial yarn, synthetic fibers, polymer resins,

packaging films, automotive finishes, crop protection

products, and industrial chemicals. We sell to

approximately 3,000 customers in Canada, the United

States and 40 other countries.

February 11, 2002 DuPont

DuPont Aligns Businesses By

Markets, Technologies; Forms Textiles & Interiors

Subsidiary

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/content/US/en_US/news/releases/2002/nr02_11_02.html

Taking the next step in its

transformation to a sustainable growth company, DuPont today

announced the alignment of its businesses in five market- and

technology- focused growth platforms and the creation of a

Textiles and Interiors subsidiary.

The growth platforms are: DuPont Electronic &

Communication Technologies; DuPont Performance Materials;

DuPont Coatings & Color Technologies; DuPont Safety &

Protection; and DuPont Agriculture & Nutrition.

2003/8/11 DuPont

DuPont Confirms Negotiations With Koch Industries On Possible

Sale of DuPont Textiles & Interiors

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/content/US/en_US/news/releases/2003/nr08_11_03a.html

DuPont today announced that

it is in exclusive negotiations with subsidiaries of Koch Industries Inc., of Wichita, Kansas, regarding the

possible sale of DuPont Textiles & Interiors (DTI). The

company informed employees today that Koch representatives

would be visiting DTI sites as part of the due diligence

process.

2003/7/16 DuPont China

DuPont Performance

Coatings to Expand Business in China

http://www.collision-insight.com/news/20030717-dupont.htm

DuPont Performance Coatings and Beijing Red Lion Coatings

Company Limited, Beijing, have signed agreements forming two

automotive coatings joint ventures, one in Beijing and the

other in Changchun, [吉林省]長春, China. Both ventures have received

final government approval and will have a share distribution

of 60 percent DuPont and 40 percent Red Lion. Operations have

already begun.

Through the agreements, DuPont has increased its stake in an

existing joint venture and has entered into a second joint

venture, both named "DuPont Red Lion," with the objective of

modernizing coatings production to support the Chinese

automotive industry with locally manufactured and technically

serviced products.

DuPont

Red Lion Coatings (Beijing) Co., Ltd.

In the Chinese capital of Beijing, DuPont Red Lion will build

a new production site for OEM paints as well as an

application center.

(* DuPont has increased its stake in Herberts-Akzo-Red Lion

Automotive Coatings (Beijing) from 51%, to 60%, by acquiring shares

from Akzo Nobel and renamed the business DuPont Red Lion

Coatings (Beijing) Co.

DuPont acquired its original stake in the jv through the 1999 acquisition

of the Herberts coatings business from Hoechst. )

DuPont

Red Lion Coatings (Changchun) Co., Ltd.

The Changchun site in the North of China, in the vicinity of

First Automotive Works and its joint venture with Volkswagen,

is to be expanded and modernized at an incremental cost of

$15 million (USD). This investment will enable DuPont Red

Lion to supply its customers with coatings that meet the

highest international standards for both product quality and

technical service.

The joint venture in Changchun, was originally established in

1995 by TOA International Company, Ltd. (Thailand) and

Changchun City Paint Factory (CCPF) as "TOA-CPF Paints

Co. Ltd." (TCPC). Red Lion acquired the interest of CCPF

in 2001. DuPont is acquiring the interests of TOA in the

previous venture.

Beijing

Red Lion Coatings Company Limited

Red Lion, founded in 1952, is one of China's largest coating

producers. Its trademark, Red Lion(TM), is named a

"Famous Trademark" by the governing Beijing

authority. Red Lion provides a variety of high quality

coatings to market and its products are widely used in

various industries such as automotive, machinery, sheet steel

and buildings.

February 6, 2004 PR

Newswire

DuPont Increases Equity Position and Outlines Investment Plans

For Automotive Coatings in China

DuPont Performance Coatings has acquired additional equity in its

DuPont Red Lion joint ventures in Beijing and Changchun, China,

to reinforce its position as the leading coatings supplier to the

growing Chinese automotive industry.

With government approvals obtained at year-end 2003, DuPont now

has increased its equity position in the DuPont

Red Lion - Beijing joint venture to 76 percent from 60 percent and has renamed it "DuPont Red Lion

(Beijing) Company, Limited" (DRBC). The joint venture in Beijing was

initially formed in 1992. DuPont also acquired 100 percent ownership of its other DuPont Red Lion joint

venture in Changchun,

China, by purchasing the remaining 40 percent interest held by

Red Lion. The company will be known as "DuPont Performance

Coatings - Changchun"

(DPCC). The DuPont and Red Lion joint venture in Changchun was

initially formed in 1995.

2003/9/24 DuPont

DuPont Fluoroproducts Announces Land Reservation in China

Sets Stage for Series of

Investments Over Next Several Years

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2003/nr09_24_03a.html

DuPont Fluoroproducts and DuPont China

Holding Co., Ltd., announced they have signed a land

reservation agreement with officials of the Hai Yu Township

of the Changshu常熟 Municipality in the

Jiangsu province 江蘇省of the People's

Republic of China.

The first

facility planned for the Changshu site, pending approval and

formation of a joint venture between DuPont and

Zhonghao 中浩New Chemical Material

Co. Ltd.

Zhonghao New Chemical Material Co. is an affiliate of the

Shanghai 3F New Materials Co., Ltd., which also is a

leading manufacturer of fluoropolymers in China.

About DuPont

Fluoroproducts

http://www.dupont.com/teflon/newsroom/about.html

Fluoroproducts

is a DuPont strategic business unit (SBU) that manufactures

and markets high-performance chemicals and polymers

worldwide, serving customers in the telecommunications,

aerospace, refrigeration, air conditioning, pharmaceutical,

automotive, electronics, chemical processing, and housewares

markets.

1999 Revenue: About $1.5 billion

Employees: 3,200 worldwide

Major Products and Brands

Major product lines include Suva® refrigerants, Teflon® and Tefzel®fluoropolymer resins,

SilverStone® non-stick finishes,

Tedlar® polyvinyl fluoride film, Formacel® blowing agents, Vertrel® cleaning agents, Dymel® propellants, Zyron® electronic gases, and Nafion® membrane products.

2003年9月8日 デュポン

デュポン テキスタイル アンド

インテリア、社名を「インビスタ」に変更

http://jp.dupont.com/jpcorp/news/03-9-8Invista.html

デュポン

テキスタイル アンド インテリア(DTI)(米国デュポン社の100%子会社)は、9月4日(米国時間)、社名を「インビスタ」へと変更すると発表しました。

新社名「インビスタ(INVISTA)」は、技術革新(innovation)とビジョン(vision)という概念を組み合わせたものです。

2002年2月、デュポン社は100%子会社のDTI(現インビスタ)を設立し、2003年末までに同社から分離独立させると発表しました。2003年8月11日には、デュポン社は、DTIの売却に関してコーク・インダストリーズ社(本社:米国カンザス州ウィチタ)との独占交渉に入ったと発表しました。

2003/11/17

DuPont

DuPont

and Koch Subsidiaries Agree On Sale of INVISTA Fibers Unit

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/content/US/en_US/news/releases/2003/nr11_17_03a.html

DuPont

and Koch Industries, Inc. today announced they have reached a

definitive agreement to sell INVISTA, formerly DuPont

Textiles & Interiors, to subsidiaries of Koch for $4.4

billion in cash. The two subsidiaries are KED Fiber Ltd. and

KED Fiber, LLC.

2004/4/8

DuPont

DuPont

Provides Update on Sale of INVISTA TM

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2004/nr04_08_04a.html

DuPont

today announced that KED Fiber Ltd. and KED Fiber, LLC,

subsidiaries of Koch Industries, have advised DuPont that

they intend to accelerate the closing of the sale of INVISTA to April 30,

2004. DuPont and the Koch companies also have agreed to an

amendment of the purchase agreement, adjusting the sale price

to $4.2 billion, including the assumption of debt and certain

joint venture and equity interests covered under a

non-binding letter of intent. No further details were

disclosed.

2003/11/4 DuPont

DuPont to Locate

Asia Pacific Research & Development Center in Shanghai

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2003/nr11_04_03a.html

DuPont today

announced it will construct a $15 million corporate research

and development (R&D) facility near Shanghai to support

growth in the Asia Pacific region.

Globally, DuPont has more than 75 R&D facilities with

over 40 in the United States and more than 35 in 11 other

nations. The Shanghai research and development (R&D)

center will be the third major research facility for DuPont

outside the United States; the others are in Switzerland and

Japan.

December 01, 2003 DuPont

DuPont Takes Actions to Achieve USD 900 Million Annualized Cost

Improvement in 2005

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/content/US/en_US/news/daily/2003/dn12_01_03.html

DuPont today announced that it

will take aggressive actions to ensure its global competitiveness

as a more focused, science- based company following the

separation of INVISTATM. Included are productivity and

organizational actions that will achieve a USD 900 million cost

improvement in 2005. In

addition, the company will undertake actions that strengthen its

ability to achieve 6 percent annual revenue growth - a key

objective in its ongoing transformation to become a sustainable

growth company.

DuPont will take the following actions:

| ・ |

Reduce

Costs from INVISTA Separation. |

| |

DuPont will

realize a total of USD 200 million in fixed cost

reductions to offset

residual costs from the anticipated separation of

INVISTA. USD 100 million will be realized in 2004, and

the full USD 200 million in 2005. |

| |

|

| ・ |

Leverage

and Strengthen Infrastructure. |

| |

Infrastructure

actions are expected to achieve USD 250 million in fixed

cost reduction in 2004, and the full USD 500

million in 2005. |

| |

|

| ・ |

Improve

variable margin. |

| |

These actions are

expected to realize a USD 100 million variable margin

improvement in 2004, and the full USD 200

million improvement in 2005 - mainly through cost reduction. |

| |

|

| ・ |

Improve Growth

Capabilities. |

| |

Recognizing that its

leadership and functional expertise is concentrated in

the United States and Western Europe, DuPont will

rebalance resources towards emerging markets, where much

of its growth will occur in the coming years. Initial

focus will be on China, where the company already has a

strong base. Other areas of interest include Central &

Eastern Europe and Brazil. Separately, DuPont has undertaken

to comprehensively and systematically improve its

marketing and sales capabilities across its businesses,

and to center and strengthen its marketing and sales

support functions. |

January 12, 2004 DuPont

DuPont Announces Organizational Alignment to Drive Growth

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2004/nr01_12_04a.html

DuPont today

announced that it is aligning its organizational structure to implement the

customer- and market-focused growth and productivity actions announced on Dec. 1,

2003.

"This alignment will greatly enhance our ability to

deliver over $1 billion in revenue growth every year, said

DuPont Chairman and CEO Charles O. Holliday, Jr. "By

streamlining our internal structure and leveraging functional

capabilities, we will enable our businesses to focus on

meeting the needs of customers wherever they are in the

world. We will fully capitalize on the global scope and scale

of DuPont to win in the marketplace and achieve our mission

of sustainable growth."

February 26, 2004 DuPont

Chad Addresses Morgan Stanley

Investor Conference

DuPont Chairman and CEO Chad Holliday yesterday addressed

industry analysts and investors attending the Morgan Stanley

Basic Materials Conference in New York City.

Presentation

http://media.corporate-ir.net/media_files/NYS/DD/presentations/dd_022304.pdf

March 05, 2004 デュポン

米国デュポン社、中国を拠点とするソリッドサーフェス(人工大理石)メーカーの買収を発表

http://jp.dupont.com/jpcorp/news/030504CorianChinaBusiness.html

世界初の人工大理石であるデュポンTMコーリアン®(Corian®)を製造するデュポン サーフェス事業部は、デュポン社の戦略の一環として、成長市場における地位を強化する目的で、広州およびXishuiの両市にある広州モンテリ社の既存の製造施設を従業員400人とともに買収しました。この買収には、広州モンテリ社がこれまで販売してきた様々な人工大理石ブランドならびに中国全土を網羅する同社の販売流通ネットワークが含まれています。

「中国を代表する人工大理石ブランドのモンテリ®(Montelli®)は、高い品質と強力な販売流通ネットワークで高い評価を受けています。

デュポンが製造販売する独創的な人工大理石コーリアン®は、ニューヨーク州バッファローのヤーキース工場、エムアールシー・デュポン社の富山工場及び、韓国の蔚山(ウルサン)工場で引き続き製造します。

デュポン サーフェス事業部は、デュポンの事業部門の一つとしてデュポンコーリアン®およびZodiaq®(ゾディアック)を製造販売しています。デュポンコーリアン®は、人工大理石として知名度の高い世界的なブランドです。さらに詳しい情報はwww.corian.comをご覧下さい。Zodiaq®(ゾディアック)は、純粋な石英を原料とする高級面材です。さらに詳しい情報はwww.zodiaq.comをご覧下さい。

2004/3/8

中国・ASEANニュース速報

デュポンは先月17日、すでに新会社「杜邦応用面材(広州)」を設立。今後は蒙特利のブランドや生産設備、販売ネットワークを利用して、中国の高分子複合材料市場におけるシェアをこれまでの2倍以上まで拡大する計画としている。

蒙特利

Montelli Industrial

Enterprises Limited (China) manufactures Solid Surfacing

Material. With the know-how from the United States, Montelli (China) established on

October 1995 and rapidly expanded to become the leading

manufacturer of Solid Surfacing Materials in China.

Montelli (China), located in Guangzhou, occupies an area of

60,000 sq. meters and employs more than 500 workers. Besides,

Montelli (China) is the only manufacturer in China which has

adopted the "Continuous Manufacturing Process" for

the production of Solid Surfacing Material - an ISO9001

certified process which ensures the quality of all products

maintains at a high and stable standard. Moreover, with the

introducing of this process, our factory is capable to

produce 1,200,000 sq. meter of Solid Surfacing Material

annually to satisfy the growing demands from all over the

world.

USA Montelli Industries, Inc.

http://www.montelli.net/

March 24, 2004

DuPont

DuPont

Inaugurates Corian® Plant in Korea

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/content/US/en_US/news/daily/2004/dn03_24_04a.html

DuPont

Surfaces recently inaugurated a new Corian® manufacturing

plant in Ulsan, Korea.

* The

Ulsan plant replaces the earlier facilities at Anyang, which was

established in 1999.

2004/4/30 Dupont

Koch Subsidiaries Buy Fibers Unit from DuPont

New INVISTA combines strengths - in nylon, spandex, polyester and

resins - of INVISTA, KoSa

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2004/nr04_30_04a.html

DuPont

and subsidiaries of Koch Industries, Inc. today finalized the

sale of INVISTA, formerly DuPont Textiles & Interiors, for

$4.2 billion, including the assumption of debt and certain joint

venture and equity interests covered under a non-binding letter

of intent. Ownership will transfer at 5 p.m. EDT.

*Subsidiaries of Koch Industry

own polyester manufacturer KoSa.

2004/5/20 デュポン

米国デュポン社、中国での特殊製品群の生産能力を拡大

米国デュポン社(本社:デラウェア州ウィルミントン、会長兼最高経営責任者:チャールズ・O・ホリデー・ジュニア)は、5月19日(中国・上海時間)、中国での専用製造ラインによる特殊製品群の生産能力の拡大に関して、中国の上海にある樹脂加工メーカーと合意したことを発表しました。今回の生産能力拡大は、市場での合成樹脂特殊製品群に対する需要増加に応えるもので、2004年第4四半期から実施する予定です。

対象となる製品群は、ザイテル®ナイロン樹脂の特殊製品(HTN芳香族ナイロン樹脂を含む)、Thermx®

(サーミックス)PCT樹脂、ライナイト® PET樹脂、クラスティン®PBT樹脂、ハイトレル®熱可塑性ポリエステル・エラストマー、およびゼナイト®液晶ポリマーです。

2004/5/26 DuPont

DuPont

and Tate & Lyle Form Bio-Products Joint Venture

New

Company Will Replace Petrochemicals with Renewable Resources

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2004/nr05_26_04a.html

DuPont

and Tate & Lyle PLC today announced

a joint venture to create products from renewable resources such

as corn for numerous applications including clothing, interiors,

engineered polymers and textile fibers.

The

new company - DuPont Tate & Lyle BioProducts, LLC - is equally

owned by DuPont and Tate & Lyle and will be based in

Wilmington, Del. The company plans to construct its initial

commercial manufacturing plant adjacent to an existing facility

in Loudon, Tenn., with startup scheduled for 2006. A pilot

facility in Decatur, Ill. has been operating for several years.

The

joint venture will use a proprietary fermentation and

purification process developed jointly by DuPont and Tate &

Lyle to produce 1,3 propanediol (PDO), the key

building block for DuPontTM Sorona® polymer.

Sorona®

3GTポリマー(ポリトリメチレンテレフタレート)

Tate & Lyle

http://www.tateandlyle.com/TateAndLyle/ir_our_business/company_overview/default.htm

Tate & Lyle is a global

leader in carbohydrate processing. Our brands and high

quality ingredients add value to consumer products around the

world. Our core competence is to take basic carbohydrates -

corn, wheat or sugar - and add value to these raw materials

through technology. As a result of continuous innovation we

are able to offer an ever-wider product portfolio of

versatile and functional sweeteners, starches, proteins and

acidulants.

2004/6/30 DuPont

DuPont Acquires BioSentry's Animal Health Business Assets

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2004/nr06_30_04a.html

DuPont

today announced it has acquired the animal health business assets

of BioSentry, Inc., a leading biosecurity company providing

animal health prevention programs in 50 countries. Financial

terms were not disclosed.

"This year's Avian Influenza outbreaks further demonstrate

the importance of preventive biosecurity to protect operations

and the food chain from the effects of virus and disease. This

acquisition will enable us to further meet existing and emerging

needs, contributing to the continued growth of our overall Clean

and Disinfect business."

In 2003, DuPont acquired United Kingdom-based Antec International. Antec products

are used throughout the world to protect global food supplies

from disease-causing agents such as the Avian Flu and Foot and

Mouth Disease and the public from pathogens such as the

Norwalk-like virus that has impacted the cruise ship industry.

Antec products are used not only to attack disease outbreaks but

also as a preventative agent, eliminating the germs before they

can cause infection.

2004/7/2

DuPont and Maxygen, Inc. yesterday completed the sale of Verdia,

Inc., formerly a wholly owned subsidiary of Maxygen.

2004/6/3 DuPont

DuPont

To Acquire Maxygen Subsidiary Verdia

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/content/US/en_US/news/releases/2004/nr06_03_04a.html

DuPont

(NYSE: DD) today announced that it has signed definitive

agreements to acquire Verdia, Inc., a wholly owned

subsidiary of Maxygen, Inc. (Nasdaq: MAXY)

headquartered in Redwood City, Calif.

By

purchasing Verdia, DuPont will have worldwide, royalty-free,

exclusive rights to use Maxygen's MolecularBreedingTM directed

evolution platform technologies (gene shuffling) for agricultural

applications across its Agriculture & Nutrition platform. All

Verdia employees will receive offer letters for employment with

DuPont, and DuPont plans to retain Verdia's name, its bay-area

offices and the Verdia leadership team.

Maxygen plans to use the proceeds from this transaction to fund

the advancement of its human therapeutic development programs. The company has

an improved interferon alpha in development with Roche for the

treatment of hepatitis B and C infections - an improved

interferon beta for multiple sclerosis and a novel G-CSF for

neutropenia both of which Maxygen plans to advance into clinical

development over the next 18 months.

Maxygen

http://www.maxygen.com/about.php

Maxygen

was founded in 1997 to develop important commercial products

through the use of biotechnology. Since then, we have

established a focus in human therapeutics, formed multiple

partnerships with leading pharmaceutical and biotechnology

companies, built a robust pipeline of product candidates and

created industrial businesses with near-term product

revenues.

Maxygen

is a leader in the evolution and optimization of genes and

proteins for the creation of improved human therapeutic

products. Our business model focuses on cost-effective

development and commercialization of multiple products, on

our own and with partners.

Verdia http://www.verdiainc.com/

Verdia

is dedicated to becoming a global leader in providing

proprietary product solutions to important commercial

problems in plant-based businesses through the application of

advanced trait optimization methods.

Our proprietary MolecularBreedingTM directed

molecular evolution enables us to enhance the potency,

functionality, and utility of proprietary protein-based

actives, the starting point for competitive transgenic

products. Verdia has validated its capabilities for rapidly

developing superior transgenic products through

collaborations with industry leaders and currently has seven

products in commercial development with our partners.

Our technology has the potential to add value to the two

major components of transgenic agriculture: input traits,

which can reduce a grower's production costs, and output

traits, which can enhance the functionality and value of

plant-derived products. Our initial focus is on input traits,

such as transgenic solutions for crop disease, pest and weed

management as genetic-based product alternatives to the $28

billion crop protection chemical market. In the future, we

intend to enter the output trait and value added market

segments through research and development partnerships with

major companies.

2004/8/25 DuPont

DuPont Opens $130 Million Facility to Produce Innovative Nonwoven

Fabrics

Advanced Composite Technology to enhance protection, comfort for

healthcare professionals

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2004/nr08_25_04a.html

DuPont

today opened a new $130 million facility here to produce

innovative nonwoven fabrics born from a revolutionary composite

technology that provides users with advanced levels of both

comfort and protection.

DuPont's proprietary Advanced Composite Technology (ACT) blends

the ideal properties of two different raw materials to create

nonwoven fabrics that meet specific needs. More than 20 new

patents were developed for this technology.

The ACT's initial product is DuPontTM SuprelTM, a highly

protective and comfortable fabric used for hospital operating

gowns and patient drapes. SuprelTM is the only

medical fabric available that is made of polyester - for

strength - and polyethylene - for silk-like

softness. Traditional single-use medical fabrics

can be uncomfortable, especially when they are worn for an

extended time, and can lack the necessary fluid barrier for

protecting today's healthcare professionals. SuprelTM has less surface

friction than other medical fabric products, allowing for greater

comfort and freedom of movement. It also transfers heat away from

the body quickly, adding to comfort in the operating environment.

SuprelTM is made from

continuous filament fibers and is very low linting.

September 29, 2004 DuPont

DuPont Electronic Technologies and Samsung Cheil Industries, Inc.

Announce Joint Venture Agreement for Flexible Circuit Materials

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2004/nr09_29_04a.html

DuPont Electronic

Technologies and Cheil Industries, Inc., part of the

Samsung Group,

have signed a 50/50

joint venture agreement,

pending local and government approvals, to establish SD Flex Company, LLC. SD Flex Company will

manufacture DuPontTM Pyralux® adhesiveless, flexible copper clad

laminate (FCCL), the material instrumental in enabling

advanced functionality and performance in displays, cell phones,

personal digital assistants (PDAs) and other electronic devices.

DuPont 2005/4/25

DuPont Announces Research Agreement with India's National

Chemical Laboratory

DuPont Continues Goal to Globalize its R&D Efforts In

Targeted Emerging Markets

http://www1.dupont.com/NASApp/dupontglobal/corp/index.jsp?page=/news/releases/2005/nr04_25_05a.html

DuPont today

announced it has signed a research agreement with the National

Chemical Laboratory (NCL) in Pune, India. Under terms of the

agreement, DuPont will have access to the talents and

capabilities of one of India's premier research and development

laboratories to grow new market-facing technologies. The first

research projects NCL will develop will be for the DuPont

Titanium Technologies business.

Asia

Chemical Weekly 2005/8/23

Dupont

decided world scale TiO2 project in Shandong

Dupont has decided to build a world scale Titanium Dioxide (TiO2)

project in Dongying (東栄), Shandong Province.

According to the industrial sources, the total investment for the

proposed TiO2 project would be USD 1 billion. In the first phase

of construction, the investment is expected as USD 700-800

million and it would have the capacity of 200 kt/a.

The world-class TiO2 project would be located in the Economic

Development Zone of Dongying City. Dongying is being famous as

the city is the location of Shenli (勝利)

Oilfield which is the second large oilfield in China, just less

than Daqing (大慶)

Oilfield.

This TiO2 project maybe start construction by the end of this

year or at the beginning of 2006; and it is expected to start up

in 2009.

DuPont thinks that Current and forecast demand for Titanium

Dioxide in Asian markets, especially China, is growing faster

than any other region of the world. The company also believe that

location of a new plant at Dongying would significantly improve

its ability to serve its own customers in these fast-growing

markets while contributing to the continued development of the

local economy.

DuPont is the world's largest manufacturer of TiO2, it operates

three TiO2 plants in the US, one in Mexico and one in Taiwan.

2005年11月21日

DuPont

米国デュポン社と中国の東営市が新たな二酸化チタン工場の建設に向けて大きく前進

米国デュポン社(本社:デラウエア州ウィルミントン、会長兼最高経営責任者:チャールズ・O・ホリデー・ジュニア)と東営市の幹部は、11月21日(米国時間)、同市の経済開発区における世界的規模の二酸化チタン工場の建設計画が節目を迎え大きく前進したことを祝いました。二酸化チタンは、塗料、プラスチック、紙業界で広く利用されている白色顔料です。

デュポンのトマス・M・コネリー上席副社長兼最高科学技術責任者、東営市がある山東省の孫守璞副省長、さらにデュポン社員、様々な政府機関、流通業者、二酸化チタンを利用するお客様を代表して参列した150名が見守る中、プロジェクトに関する合意書に署名が行われました。

この合意は、昨年3月にデュポンと東営市の間で始まった交渉の集大成であり、新工場の建設に向けた重要な一歩となるものです。関連する政府機関の承認後、新しい二酸化チタン工場のために東営市には総計10億米ドルを超える投資が行われる予定です。この合計額には、デュポンによる初期投資、工場サプライヤーの連合体による施設の建設費用、当初施設の最終的な拡大にかかる費用を含みます。新工場はデュポンが100%所有し、同社が米国以外で行う単体の投資プロジェクトとしては最大規模となります。

Jan 03, 2008 (SinoCast via COMTEX)

US DuPont says it will not give up the titanium dioxide

project in Dongying City of Shandong Province.

In 2005, DuPont signed a cooperative agreement with Dongying

government to pour about USD 1 billion in a titanium dioxide

project with an annual output of 200,000 tons after it is put

into production in 2010. The project will pay CNY 500 million

tax to Dongying government annually by then. DuPont says

China's demand for titanium dioxide is increasing year by

year.

However, Chinese experts pointed out that the project was

likely to produce hazardous waste in its production.

DuPont responded by saying that it used deep well injection

technology in a bid to avoid environmental pollution. It

targets providing technology solutions for China's energy

saving and emission reduction, as well as sustained

development.

It is not the first time that DuPont's project is doubted to

pollute the environment. Its Taiwan project was once forced

to change locations and raw material.

2007-12-19 chinadigitaltimes.net

DuPont Gets

Go-ahead on Titanium Dioxide Plant, but Triggers Concerns

- Southern Weekend

But there's a

problem: DuPont is bringing a relatively backward

technology to its China plant, whose output will dwarf

that of any domestic competitor. Environmentalists accuse

DuPont of using a production technique based on a much

higher polluting and energy-guzzling material, or

low-grade titanium feed. Some raise alarms that when the

toxic waste gets injected underground, it will be

extremely difficult to reverse the damage, which includes

possible radiation.

Despite all these

concerns, and despite DuPont's historical record of

failing to dump this low-end technique on Taiwan more

than 20 years ago, China's authorities have flashed a

green light this time.

RubberWorld

2005/9/21

DuPont, Lucite announce agreement

DuPont and Lucite International, Inc. announced Tuesday they have

entered into an agreement regarding their manufacturing

facilities at the Beaumont, Texas, Industrial Park. As part of

the agreement, Lucite now will operate the DuPont

acrylonitrile operation at the Beaumont site. They

also will take over operation of site services such as power and

utilities, for the Beaumont Industrial Park.

Lucite will offer employment to large number of DuPont employees

who currently operate the acrylonitrile plant and perform site

services work. In addition, Lucite will invest in the

acrylonitrile operation to enhance the competitiveness of the

facility. This agreement will not change

operations at other DuPont or Lucite manufacturing facilities or

the DuPont Performance Elastomers, a wholly owned subsidiary of

DuPont, facility at the Beaumont Industrial Park.

2005/12/12 デュポン・ジャパン

米国デュポン社、新たにエンジニアリングポリマーの生産拠点をシンガポールに建設

米国デュポン社(本社:デラウエア州ウィルミントン、会長兼最高経営責任者:チャールズ・O・ホリデー・ジュニア)は、12日(米国時間)

、高成長する二つのエンジニアリングポリマー、デュポンTM ザイテル(R) HTN高機能ポリアミド樹脂とデュポンTM ベスペル(R) パーツ&シェイプスについて、新たにシンガポールに設備投資を行うことを発表しました。

新工場の稼動開始時期は、需要の動向にもよりますが、ベスペル(R)は2007年、ザイテル(R) HTNは2009年を予定しています。ベスペル(R)については、デュポンは既にオハイオ州、デラウエア州、ベルギー、そして日本で生産を行っています。ザイテル(R)HTNに関してはテネシー州とバージニア州リッチモンドで生産をしています。このリッチモンド工場は2005年第2四半期に稼動を開始し、現在優れた高品質の製品を供給しています。

ザイテル (Zytel) はデュポンのナイロン樹脂。ナイロンは1938年に米国デュポン社カローザス博士によってが世界で初めて発明され、開発商品化されたことで有名。

ベスペル (Vespel) は、デュポンが開発した超耐熱性プラスチック(全芳香族ポリイミド樹脂)。エンジニアリングプラスチックのなかで最高の耐熱性と耐摩擦性を有しており、機械・電機部品をはじめ幅広い用途に使用。

DuPont News, June

28, 2006

DuPont

to Produce New High-Performance Polymers Made with Renewable

Resources

http://www2.dupont.com/Media_Center/en_US/daily_news/article20060628.html

DuPont

expects to begin production in 2007 of new high-performance

thermoplastic resins and elastomer products made from two of

its latest bio-based materials innovations. The products will be

targeted for automotive, electrical/electronic and other

industrial markets.

Intermediates

for DuPont Sorona(R) polymer and DuPont Hytrel(R) made with

renewable resources will be made from corn sugar instead of

petroleum, using a patented and proprietary process. The key

ingredient in Sorona is Bio-PDOTM, which replaces

petrochemical-based 1,3-propanediol (PDO). The new DuPont Hytrel

offering is produced using a new DuPont polyol made

with Bio-PDO. Sorona polymer for industrial

applications will be commercially available in mid-2007; and the

renewably sourced Hytrel grades will be available in late 2007.

コーンシュガー

: トウモロコシから作られる砂糖

Loudon,

Tenn., will be home for the world’s largest aerobic fermentation

plant for the production of Bio-PDO. The plant is owned and

operated by DuPont Tate &

Lyle BioProducts LLC, an equally owned joint venture of

DuPont and Tate & Lyle. It is scheduled to come on stream

later this year and will have the capacity to produce 100 million

pounds of Bio-PDO (over 45,000 metric tons) per year.

Bio-PDO+TPA or DMT → Sorona polymer → 3GT繊維、PBTと同様の性能と成形性の高機能ポリマー

Hytrel

化学構造は、ハードセグメント(PBT)とソフトセグメント(ポリエーテル)とのブロック共重合体

ソフトセグメントにバイオベースのポリオールを使用することで、石油由来のポリオールを代替

ハイトレル®は、高性能エンジニアリングエラストマー

ハイトレル®は、米国デュポン社が開発した、熱可塑性ポリエステルエラストマーです。

日本では、東レ・デュポン社(株)が製造、販売を行っています。

ハイトレル®は、ゴム弾性をもちつつ、エンジニアリングプラスチックの特長である高機能性、良成形加工性も備えています。

ハイトレル®は、熱可塑性エラストマーの中でも、最も高性能で、信頼性に優れた材料です。

ハイトレルの化学構造は、ハードセグメント(PBT)とソフトセグメント(ポリエーテル)とのブロック共重合体です。

2003年.

アメリカのグリーンケミストリー賞 Alternative

Solvents and Reaction Conditions Award

DuPont、 Microbial Production of 1,3-Propanediol

繊維用ポリマーDuPont Sorona

の原料、1,3-プロパンジオールの製造を再生可能原料から変性バイオ触媒で行い、環境負荷の低減、コスト削減、効率改善を実現した。

コーンスターチからのグルコースをグリセロールに変えるイーストの遺伝子と、グリセロールを

1,3-プロパンジオールに変えるバクテリアの遺伝子をホスト微生物に組み込み、グルコースからプロパンジオールへの

1 段での転換を最大にし、バイオマス・副生物を最少にすることに成功した。(この遺伝子組換えは

DuPont と Genecor International の共同開発)

1,3-プロパンジオールのポリエステルである Sorona

は、分子鎖にキンク(捩れ)を有し、弾性、柔軟性、防汚性、染色堅牢性などに優れて、衣類の他 自動車内装、家具用に適する他、樹脂としてはバリア性に優れているという特性をもっているが、石油化学からの製造ではモノマーコストを安く出来なかった。バイオ法がそのコストの問題を解決した。

Sorona® 3GTポリマー(ポリトリメチレンテレフタレート)

2006 年8 月1 日

デュポンジャパン

小林昭生デュポン(株)社長がDAP

社新会長に内定

デュポン(株)新社長には天羽 稔副社長が昇格

デュポン株式会社(本社:東京都千代田区、社長:小林昭生)は、本日、2006年9月1日付けで小林昭生社長がデュポン・アジア・パシフィック

リミテッド(DAP 社)代表取締役会長 兼デュポン㈱取締役相談役に就任し、その後任として、デュポン(株)取締役副社長兼エンジニアリングポリマー事業部アジア太平洋地域リージョナルディレクターの天羽 稔がデュポン(株)の代表取締役社長に昇格する役員人事を発表しました。

小林社長は、2003 年1 月にデュポン(株)社長に就任し、低迷する日本経済の中にあって、これまで強力なリーダーシップを発揮して、過去3

年余、デュポン(株)に年率二桁の成長をもたらしました。その原動力となったのは同社長が打出した、日本を再生させる「デュポン・ジャパン・ルネッサンスプラン」です。同プランは、①顧客の声に迅速に対応し、品質改善・供給の安定確保に努めて顧客満足度を向上させる事業戦略、②若手や女性の積極的な登用・活用を図る人材戦略、③社内活性化や業務改革を主とするインフラ整備戦略――を三つの柱としています。昨年度の日本におけるデュポン・グループの売上高は3,300

億円に拡大しています。

天羽新社長は、設立以来45

年の歴史を持つデュポン(株)において内部から昇格した初の社長となります。合成樹脂事業ではアジア太平洋地域の事業成長に貢献し、また、名古屋にデュポン・オートモーティブ

センターを設立して多くの事業部がかかわる自動車関連事業をOne

DuPont (ワン・デュポン)戦略に基づき主導してきました。今後は、アジア太平洋地域で合成樹脂事業を成長させた実績と事業運営の経験を生かして、合弁会社を含めた日本におけるデュポングループの更なる発展のため、業容の拡大と強固な経営基盤を構築することが期待されています。また、サイエンス・カンパニーであるデュポンの科学と技術革新を最大限に駆使し、事業部間を越えて持続可能なビジネス

ソリューションを提供するというデュポンのOne

DuPont(ワン・デュポン)戦略の更なる具現化も推進します。

米国デュポン社は、サイエンスカンパニーとして持続可能な成長を目指しています。デュポン(株)会長であるドン・ジョンソンを含めた新体制には、デュポンのグルーバル戦略と連携した事業展開を推進してリーダーシップを発揮し、更なる成長をとげることが期待されています。

DuPont Partners with

Zhangjiagang Glory Chemical Industry Co. to Produce First

Bio-Based DuPont Sorona® Polymer in Asia

DuPont

today announced a partnership with Zhangjiagang (張家港) Glory Chemical Industry Co.,

Ltd. (Glory) to produce and distribute bio-based DuPont Sorona®

(3GT 繊維) polymer, the company's latest

polymer innovation, throughout Asia. The partnership marks the

first commercial manufacturing of Sorona®

in Asia. Terms of

the agreement were not disclosed.

Located

in the Jiangsu Province in China, Glory was formed earlier

this year exclusively to produce Sorona® polymer. The company broke ground in May on

its new continuous polymerization (CP) facility, which will

manufacture Sorona® using the technology know-how

licensed from DuPont. The Glory facility is slated to start up in

the fourth quarter with plans to offer the first commercial

product in the second quarter of 2007. Glory will receive Bio-PDO from the DuPont Tate & Lyle BioProducts facility in Loudon, Tenn., and

will manufacture renewably sourced Sorona®

polymer. Once

operational, the Glory facility will be capable of producing 66

million pounds or 30 kilotonnes of Sorona® per year.

DuPont December 12, 2006

DuPont Agriculture & Nutrition Increases Investment in Plant

Biotechnology; Streamlines Nutrition and Crop Protection

Businesses

Yesterday, DuPont Agriculture & Nutrition launched a plan to increase

investment in plant genetics, biotechnology and other high-value

growth opportunities,

while further improving competitiveness in low-growth areas of

its nutrition and crop protection businesses by reducing

operating costs about USD 100 million a year.

Under the plan, DuPont will reinvest all of the USD 100 million

savings into its seed business. These actions will help expand

the company’s competitive advantage in the

seed market and increase the speed to market of seed products

with next-generation biotech traits.

“We

are aggressively adjusting our capital and resource allocation to

the highest value growth opportunities for our customers and

shareholders,” said Erik Fyrwald , group vice

president, DuPont Agriculture & Nutrition.

DuPont will consolidate manufacturing assets,

leverage technology centers and refocus product marketing

strategies in its nutrition and crop protection businesses.

| Other

growth opportunity areas in the Agriculture &

Nutrition plan include: |

| ・ |

Increased

sales and marketing resources for the seed business. |

| ・ |

Investments

in safer crop protection products by delivering our

research pipeline products, including the planned 2008

introduction of RynaxypyrTM, a next generation

ultra-low toxicity insecticide. |

| ・ |

Growth

for The Solae Company’s SoleCina - which enables

food processors to convert a proprietary blend of

vegetable and meat protein into a nutritious finished

product. |

| ・ |

Launch

of Crystalon - vertical form fill and seal liquid

packaging technology. |

| ・ |

Continued

investment in the markets of Brazil, Eastern

Europe/Russia, India and China for all businesses. |

| ・ |

Driving

growth in its portfolio of leading biofuel technologies. |

The Associated Press 2006/12/11

Monsanto Co. has improved its dealer network, taking market

share from DuPont's Pioneer Hi-Bred seed division in the

important corn seed market. It is expected to continue to do

so. Pioneer, meanwhile, is fighting back by developing new

strains of genetically engineered seeds and poses a long-term

threat to Monsanto, according to a recent report from analyst

Kevin McCarthy with Bank of America in New York.

June 07, 2001

DuPont

DuPont to Sell

Pharmaceuticals Unit to Bristol-Myers Squibb Company for $7.8

Billion; Board Authorizes New Share Buyback Program

DuPont today announced

that it has reached a definitive agreement to sell the DuPont

Pharmaceuticals Company to Bristol-Myers Squibb Company for $7.8 billion in cash. DuPont

said that it will retain its interest in Cozaar®/Hyzaar®, an antihypertensive drug

developed by DuPont and Merck, and marketed by Merck. Closing of

the sale is expected in the fourth quarter, subject to government

approvals.

DuPont plans to use a

portion of the proceeds to complete the current $2.5 billion share

buyback program

that was announced in July of last year. The remaining proceeds

are expected to be used to reduce net debt and invest in growth

opportunities aligned with the company's strategic direction.

The 1991 formation of

the DuPont Merck Pharmaceutical

Company,

a joint venture with prescription drug giant Merck and

Company, made DuPont a competitive force in the field of life

sciences.

Since the late 1950s, DuPont had conducted pharmaceuticals

research but found that it lacked the experience necessary to

expedite FDA approval for new drugs and then market them. The

1969 purchase of Endo Laboratories provided DuPont with the

successful drug Coumadin®, but pharmaceuticals remained

a marginal part of the company's business through the 1980s.

As part of an overall

strategy to expand its Life Sciences Division, DuPont formed

the 1991 venture with Merck, one of America's oldest

pharmaceutical companies with a proven ability to develop and

market new prescription drugs. The DuPont Merck

Pharmaceutical Company conducted important research in

cardiovascular, radiopharmaceutical and central nervous

system products. The company's most successful products

included Sinemet® to fight Parkinson's disease;

Cardiolite® cardiac imaging agents; and

Cozaar®, a hypertension drug discovered by

DuPont and marketed by Merck.

In 1998 DuPont bought Merck's one-half interest in the

company and began operating as DuPont

Pharmaceuticals.

This wholly owned subsidiary has developed revolutionary

products like Sustiva to fight HIV infection and continues to

research new treatments for cancer and cardiovascular

disease.

1998年2月、46歳の産業エンジニア、チャールズ・O・(チャ

ド)ホリデー・ジュニアがクロールの後任としてCEOに就任。デュポン・アジアパシフィックの社長経験をはじめ、社のあらゆる分野に実績をもつホリデーの

目も、やはり世界を睨んでいた。着任後、ホリデーがすぐさま取りかかったのは、世界市場でデュポンがさらに強みを発揮できる体制づくりだった。デュポンは

まず、医療事業で合弁していたメルク社に注目。高血圧薬コザール®、抗凝血薬クマジン®など一部のデュポン・メルクの製品は効果と収益性がすでに証明ずみ

だった。また、サスティバTMもヒト免疫不全ウィルス(HIV)用の薬として間もなく最終認可が下りる予定だった。1998年7月、デュポンはデュポン・ メルク医薬社のメルクの持ち株50%を現金26億ドルで買い取り、デュポン医薬社を設立した。

生産性向上のため、デュポンは世界の事業の構造改革を続行。2001年4月、デュポンは競争力を失ってきたポリエステルおよびナイロン工場の閉鎖を発表。

3カ月後にはポリエステル事業の一部を売却した。6月には、抗高血圧薬のコザール®とハイザール®の利権を除いた医薬品事業をブリストル・マイヤーズ・ス

クイブに78億ドルで売却するという英断を下す。医薬品事業に必要な巨額投資は、あまりにリスキーだったからだ。医薬品事業は、長年デュポンが得意とする

統合的科学の豊かな土壌であり、優れた製品を生み出してもいた。しかし、冷静な資産分析の結果、32年間育ててきた医薬品事業は、苦渋の末手放された。

ブリストル・マイヤーズ

スクイブ社への医薬品事業部の売却益aftertax 38億6,600万ドル

2001/10に医薬部門をBristol-Myers Squibb に売却

しかし、Cozaar(R)(losartan potassiumACE 阻害剤= 持続性の血圧降下薬)と Hyzaar (R) (losartan potassium with

hydrochlorothiazide ACE 阻害剤とチアジド系利尿剤

との合剤)の特許は維持しMerckにライセンスした。利益はこの特許料。

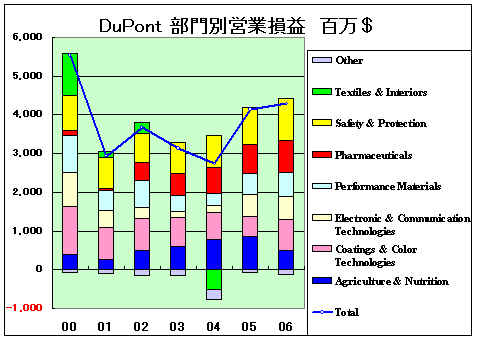

PTOI (pre-tax

operating income) excluding impact of special items

| |

1999 |

2000 |

2001 |

2002 |

2003 |

2004 |

2005 |

2006 |

| PTOI |

230 |

89 |

3,924 |

|

|

|

|

|

| excl.special |

263 |

133 |

58 |

468 |

548 |

681 |

751 |

819 |

1999/2000

decline resulted principally from significantly lower fourth

quarter sales as well as planned higher research and

development and marketing expenses

DuPont News, March

30, 2007

Sustainability:

DuPont, Honeywell Announce Refrigerants Agreement

More

than 400 million cars with air conditioning systems are on

the road globally. DuPont and Honeywell are developing

refrigerants that are more energy efficient and have low

global warming potential. One product being evaluated could

lead to a worldwide emissions reduction of greenhouse gases

equivalent to 230 million gallons of fuel per year by 2017.

Yesterday DuPont and

Honeywell announced a global joint development agreement to

accelerate the development and commercialization of next

generation, low global warming refrigerants for the automotive air

conditioning industry.

The new

refrigerants would enable automakers to meet new regulations in

Europe that require the use of low global warming potential (GWP)

refrigerants in mobile air conditioning (AC) applications.

Today's automotive

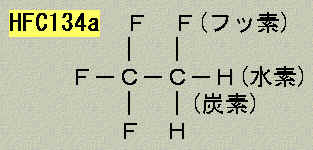

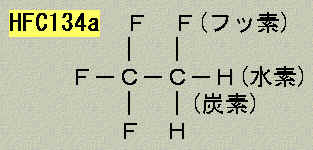

air conditioners use hydrofluorocarbon (HFC)-134a. The new regulation is scheduled to

take effect in 2011 for new model automobiles, with the

transition complete by 2017.

|

現在家庭用冷蔵庫やカーエアコンで使われている冷媒.

分子中に塩素を含まないためオゾン層破壊の可能性はないが,地球温暖化に影響を及ぼすおそれはある. |

Honeywell

International is a diversified technology and manufacturing

leader, serving customers worldwide with aerospace products

and services; control technologies for buildings, homes and

industry; automotive products; turbochargers; and specialty

materials.

June 8, 2007

DuPont

DuPont Tate & Lyle

Joint Venture Officially Opens $100 Million Bio-PDOTM Facility - the World's First to

Produce Propanediol From Corn Sugar

U.S. Secretary

of Energy Bodman Recognizes Advancements in Bio-Based Technology

DuPont Tate & Lyle Bio

Products, LLC,

an equally owned joint venture of DuPont and Tate & Lyle,

today marked the growing demand for products made from its

revolutionary Bio-PDO product. U.S. Secretary of Energy Samuel W.

Bodman joined senior leaders from DuPont, Tate & Lyle, the

joint venture and their customers to see the new production

facility first-hand and recognize its official opening.

The

Loudon facility produces 1,3-propanediol (Bio-PDO) from renewable resources - in

this case corn sugar - making it the first facility in the world

to manufacture this new bio-based product. Bio-PDO is a

versatile, biodegradable and high-performance ingredient that can

be used in cosmetics, liquid detergents and

industrial applications such as anti-freeze and many other

applications that currently use glycols. It also can be used as a monomer

to produce unsaturated polyester resins as

well as other specialty polymers such as DuPont Sorona® (3GT 繊維)and the latest renewably sourced

polymer, DuPont Cerenol. In addition, renewably sourced

Hytrel® thermoplastic elastomers and a new

line of renewable DuPont automotive finishes are two new product

lines scheduled to be launched later this year. The first

commercial product was sold in November 2006, and demand for new

uses of Bio-PDO continues to grow with nearly a dozen product

applications to date.

DuPont Cenerol is a family of

renewably sourced, high-performance polyols (polyetherdiols).

The

joint venture uses a proprietary fermentation process developed

jointly by DuPont and Tate & Lyle to produce Bio-PDO using

corn sugar instead of petroleum-based feedstocks. The production

of Bio-PDO consumes 40 percent less energy and reduces greenhouse

gas emissions by 20 percent compared to petroleum-based

propanediol. Annual production of 100 million

pounds of Bio-PDO

will save the energy equivalent of over 15 million gallons of

gasoline per year, or enough to fuel more than 27,000 cars - over

half the cars in Loudon County, Tenn.

Bio-PDO

is available in two grades: Zemea and Susterra propanediol. Zemea

has been developed for the personal care and liquid detergent

categories where high purity level and low irritation are key

product requirements. Susterra propanediol is ideal for

industrial applications such as de-icing fluids, anti-freeze and

heat transfer fluids, where its low toxicity and biodegradability

are beneficial. To learn more about Susterra or Zemea

corn-derived propanediol, visit www.duponttateandlyle.com.

Today's event was webcast and can be viewed at: http://mediasite.advancedav.com/dupont/register.html.

2006/12/06

デュポン テイト・アンド・ライル

バイオプロダクツ社 世界初、トウモロコシ由来のプロバンジオールを生産開始

-米国テネシー州の総工費一億ドルの工場が稼動-

米国デュポン社(本社:デラウエア州ウィルミントン、会長兼最高経営責任者、チャールズ・O・ホリデー・ジュニア)と英国のテイト・アンド・ライル社の折半出資による合弁会社、デュポン

テイト・アンド・ライル

バイオプロダクツ社(DuPont Tate & Lyle Bio

Products, LLC)は、11月27日(米国時間)、米国テネシー州ラウドンに建設した総工費1億ドルの製造拠点から、デュポンTMBio-PDOTM製品の出荷を開始したと発表しました。ラウドン工場は、再生可能な資源としてトウモロコシの糖分から1,3プロバンジオール(Bio-PDOTM)を製造する施設で、この新しいバイオベース製品の製造拠点としては世界初となります。

DuPont News, August 2,

2007

DuPont

Settles Patent Infringement Case Against Chinese Company

DuPont

has settled a patent infringement lawsuit it filed earlier this

year against Trustchem Co., Ltd., also known as Jiangsu Trustchem

Chemicals Co., Ltd.,

in China. Under the terms of the settlement,

Trustchem will pay monetary compensation and make a public

apology to DuPont for losses resulting from Trustchem actions.

Financial terms of

the agreement were not disclosed.

DuPont

initiated the lawsuit in the Nanjing, Jiangsu Province in March

in response to illegal Trustchem sales of agricultural products

containing rimsulfuron, which are protected by a DuPont

patent in China. Rimsulfuron is an active

ingredient in crop protection herbicides that are marketed around

the world under the Titus®, Matrix®

and Resolve®

trademarks.

This

lawsuit represents part of an ongoing DuPont Crop Protection

program to protect its intellectual property rights worldwide.

Based on these

investigations, DuPont has filed similar patent infringement

actions against several other companies, issued numerous

"cease and desist使うことをやめる " letters and is actively

investigating several other businesses in China that are

suspected of violating DuPont patents.

"DuPont

aggressively protects its intellectual property and will enforce

its rights to prevent counterfeiting of its product, infringement

of its patents and trademarks, theft of its trade secrets and

other illegal activities," said Glen Baldwin, lead counsel

for DuPont Crop Protection. Through vigorous enforcement of

its intellectual property rights, DuPont intends to preserve the

value of its proprietary products and protect the best interests

of its customers, particularly growers who have come to rely on

the quality of DuPont products.

| 米国デュポン社により開発されたスルホニルウレア系の除草剤で極めて低薬量で1年生雑草に効果を発揮します。日本芝に対する安全性に優れ、また、発生してからのスズメノカタビラにも優れた効果を示すことから、広く使用されています。 |

| 種別:除草剤 適用場面:ゴルフ場等 |

DuPont News, August 22, 2007

New

Monomer Material to Reduce Shrinkage of Dental Composites --

Putting Science to Work

DuPont

has signed an agreement with GC Corporation of Tokyo, Japan, a major global

manufacturer of dental materials and equipment, to provide

next-generation dental monomer technology that reduces the

shrinkage of dental composites.

DuPont News,

August 23, 2007

Expanding

to Support Asia Growth for Engineering Resins

DuPont

has enhanced its global manufacturing network in support of

strong Asia demand for its engineering resins through a 20,000-tons-per-year

expansion at its Ulsan, Korea, compounding facility for nylon

resins.

The

capacity expansion is in response to rapid growth in demand for

DuPont Zytel® nylon resins in the region,

particularly for automotive applications, and complements other

recent engineering polymers investments in Singapore for DuPont

Zytel® HTN high-performance polyamide and

DuPont Vespel® parts and shapes.

DuPont’s Engineering Polymers business

also has a significant presence in the company’s Shanghai research and

development center and in the DuPont Nagoya, Japan, Automotive

Center.

$500

Million Expansion Planned for Kevlar®

DuPont plans to invest

over USD

500 million in a multi-phase production expansion for its

high-performance Kevlar®

para-aramid

brand fiber, starting

with a Kevlar® polymer expansion in Richmond,

Va., later this year. For DuPont, a world leader in

para-aramid sales, this expansion would increase Kevlar®

capacity

by more than 25 percent when complete in 2010 and

represents the largest Kevlar® expansion since the product was

introduced in 1965. Details about additional expansion

phases will be announced at a later date.

The

Associated Press September 21, 2007

China's

Sinopec in chemical joint venture with DuPont unit

China Petroleum &

Chemical Corp., or Sinopec, has formed a chemicals joint venture

with a unit of U.S. company DuPont Co., it said Friday.

Production of ethylene vinyl

acetate resins

- used in products such as packaging, adhesives, footwear and

clothing - is due to begin late next year at a new plant to be

built by the venture, Sinopec said.

"The new facility

will help meet fast-growing demand for EVA products in

China," Sinopec said in a statement on its Web site.

Sinopec

will own 55 percent

of the joint venture, which will have an annual capacity of

around 60,000 tons. The remaining 45 percent will be

owned by DuPont Packaging & Industrial

Polymers.

No details were given on

the level of investment involved.

Production of EVA,

used in products such as packaging materials, adhesives,

footwear and clothing, is due to begin in late 2008 at a new

plant to be built at the existing facility of Sinopec

Beijing Yanshan Company in Beijing.

The plant will be the

first in China to make DuPont's Elvax EVA.

2007/10/15 Asia

Chemical Weekly

Sinopec and Dupont

set up EVA jv in Beijing

On late Sep. 2007, Sinopec and Dupont set up a 55:45 EVA

(Ethylene Vinyl Acetate) jv in Beijing.

Named as Beijing Huamei (華美) Polymer

Company,

the jv project is located in the existing site of Yanshan

Petrochemical, a subsidiary of Sinopec.

The project has got the approval from government in Mar,

2007. With investment around USD 75 million, the jv project

will have EVA capacity 60,000 ton/year. It is expected to

start up by the end of 2008.

EVA production technology will be provided by Dupont and

ethylene feedstock will be sourced from Yanshan Petrochemical

Co.

The new facility is hoped to meet the fast growing demand for

EVA products in China, according to the industrial observers,

the EVA consumption, such as packaging, footwear, adhesives,

etc are growing rapidly in China.

Currently, there are two EVA producers in China, Beijing

Dongfang (東方/Oriental ) Petrochemical, a

subsidiary of Sinopec has capacity of 40,000 ton/year and

YPC-BASF has capacity of 200,000 ton/year.

China imported 394 kt EVA in 2005 and 368 kt in 2006. The

import of EVA is estimated at 370 kt in 2007 according to the

data from China Customs.

2007/10/11

DuPont ordered to provide medical monitoring in Harrison County

DuPont Co. has been ordered to provide medical monitoring for

Harrison County, West Virginia residents who were exposed to

dangerous chemicals at a waste site.

A Harrison County jury ruled Wednesday that DuPont must

finance monitoring for about 7,000 residents who were exposed to

arsenic, cadmium and lead contamination. The verdict is the result of the

second phase of a class-action lawsuit filed by 10 residents of Spelter.

The residents accused DuPont of deliberately dumping dangerous

heavy metals on an industrial site in Spelter, causing the

contamination.

DuPont must finance the medical monitoring for

the next 40 years,

attorney Mike Papantonio said. Papantonio is representing the

class.

October 25, 2007

DuPont

DuPont Announces

Nanotechnology Alliance that Combines the Best of Polymers with

the Best of Metals

DuPont today announced an alliance

with Canada-based Morph Technologies Inc., Integran Technologies

Inc. , and U.S.-based PowerMetal Technologies to develop and

commercialize a nanocrystalline metal/polymer

hybrid technology

that will be used to manufacture extremely lightweight components

with the strength and stiffness of metal and the design

flexibility and lightweight benefits of high-performance

thermoplastics.

“DuPont has consistently led the

industry in providing metal replacement solutions. Now we are

turning traditional plastic/metal hybrid technology inside-out with an innovative ‘metal over plastic’ technology that delivers not only a

step-change in performance, but also provides product designers

with a technology that can help shift the current paradigm,”

Keith J. Smith ,

vice president and general manager - DuPont Engineering Polymers,

said.

Morph

Technologies, Inc.

is a privately owned company charged to commercialize Integran's

proprietary nanomaterial technology for automotive applications. Integran

Technologies, Inc.

is a global leader in the development of nanomaterials, with

business operations in Pittsburgh, Pa., and Toronto, Ont.,

Canada. PowerMetal Technologies, Inc, based in Carlsbad, Calif., is a

leading supplier of nanotechnology enabled components to the

sporting goods and consumer products industries. PowerMetal is

already commercially supplying nanometal/thermoset polymer hybrid

products that apply the same concept as the alliance is

introducing for thermoplastic polymers.

Bayer's Plastic/Metal Hybrid

technology combines plastic and metal to create mechanically

interlocked structures with excellent resistance to bending,

compression and torsional loads, high energy absorption,

dimensional stability and low part weight.

Plastic/Metal Hybrid parts consist of a thin formed sheet

metal profile supported by ribbing made from Bayer's

plastics. The metal provides the required strength and

stiffness to the structure, while the plastic ribbing

provides the necessary support to prevent buckling without

adding significant weight. Already proven in the automotive

industry, other applications for Plastic/Metal Hybrid

technology include appliance substructures, television

housings, bicycle frames and in-line skate structures.

http://www.wondersforum.com/automotive.html

現在金属とハイブリッドを造る樹脂材料は,圧倒的にポリアミド6又は66である。

現在,プラスチック/金属ハイブリッド技術において最も進んでいるのは,Bayer社である。

1998年以来今日まで,およそ35の自動車部品コンポーネントが,Bayer社の材料(ナイロンコンパウンド)を使ったハイブリッド技術によって生産された。

次の2年間,シリーズ生産の予定になる開発では,20以上の自動車向け新規ハイブリッド部品技術プロジェクトが投入される。

同社は,またより機能性を増した次世代のハイブリッド技術を開発中である。

その設計コンセプトは,エアーダクト,エンジンフードマウント,上下のクロスビームと結合する中間の垂直構造,ヘッドランプマウント,ラディエータグリルマウント,バンパーカバーマウント,歩行者保護用サポート材などを含む一体コンポネントである。

屋根フレーム ボデイシェルの2側面を結合し,フロントガラスの支持部を構成する屋根フレームは,プラスチック/金属ハイブリッド技術が,ホワイトボデイに対して最初に採用された事例である。採用の理由は,全金属製に比して,約30%の質量軽減効果があること。金属対比コストパフォーマンスがほぼ同じであることだ。同社は,更に床とシャシーへの適用開発に取り組んでいる。

ライバルの開発 同じポリアミドの供給メーカであり,ライバル会社でもある,BASF社とGE

Plastics社もこれらハイブリッド技術の開発に追随している。